Description

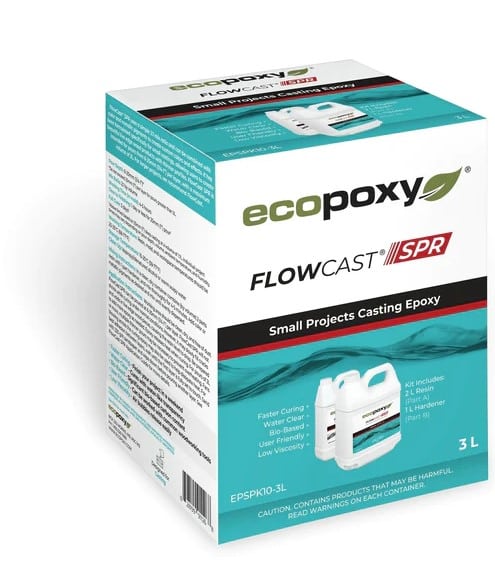

Small Projects Casting Epoxy

FlowCast SPR has been formulated specifically for small castings, allowing users to create beautiful live edge wood projects with thinner profiles such as coasters and serving trays. FlowCast SPR is intended for pours from 6-25mm (1/4-1”) per layer, with a maximum volume of 2L. Use FlowCast SPR by itself for a water-clear finish or add our Liquid, Metallic, or Glitter pigments to create custom colors and effects.

When used at one-inch thickness, you can expect your projects to be ready to demold in a day. FlowCast SPR can be worked (trimmed, routed, sanded, and finished) using the same tools you have in your woodshop.

PERFECT FOR SMALL POURS

With the ability to cast from 1/4” to 1” thick per layer in pour volumes up to 2L, FlowCast SPR is perfect for small-scale live edge wood projects.

BUBBLE-FREE CASTINGS

FlowCast SPR’s low viscosity provides excellent air release allowing trapped air to rise to the surface, significantly reducing bubbles in the cured casting.

FASTER CURING

FlowCast SPR has been formulated to cure faster making it the ideal casting epoxy for weekend projects. When used under the recommended conditions, and in accordance with Application Guide instructions, you can expect your project to be ready for finishing in a day.

OUTSTANDING TRANSPARENCY

FlowCast SPR cures to a highly desired transparent water-clear appearance. It can also be combined with Liquid and Metallic pigments to create custom colors and effects.

Mixing Instructions

Shake Part B well before use. In a clean, dry container combine (by volume) 2 parts resin with 1 part hardener and mix thoroughly for 4-5 minutes. Add color or metallic pigments as desired and mix until evenly dispersed.

Application Instructions

Working area should be clean, dry, and free of dust. FlowCast SPR can be poured at 6-25mm (1/4-1”) per layer. FlowCast SPR will not shrink while curing under normal conditions. However, it may slowly fill cracks and voids in live edge wood pieces, causing the resin level to drop. Be prepared to add more epoxy as needed.

Epoxy releases heat when curing. For pours of 2L or more, multiple thinner pours may be necessary to prevent overheating. Fans blowing across the curing epoxy may also be used to help dissipate heat. For best adhesion between layers, wait until the first layer is fully set to touch. Sand with 220 grit sandpaper and wipe down before pouring another layer.

Reviews

There are no reviews yet.