Description

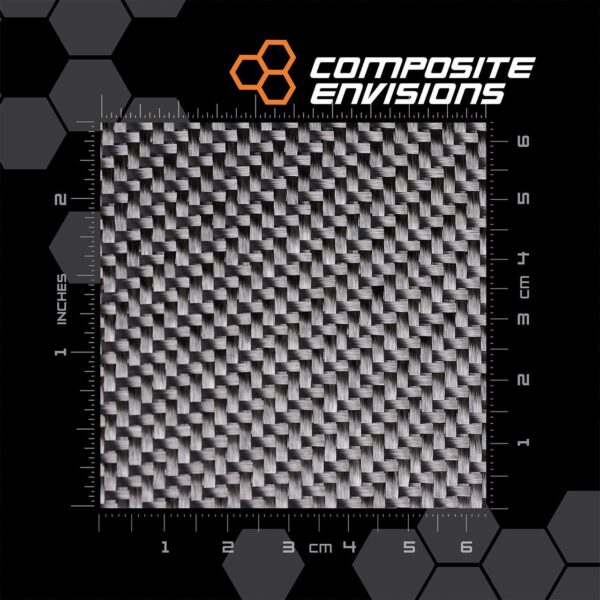

This fabric has a width of 50″, tow size of 3k, and is woven in a 2×2 twill weave. This is the most widely used weave pattern across multiple industries. This material is woven tighter than most of our competitors’ fabrics. This will help ensure a straight weave and a better looking final product.

The NT-350HT Enduredge Max represents the next generation of highly toughened prepreg resin technology. NT-350HT offers superior surface finish and laminate quality using vacuum bag only processing. One year out-time(with no refrigerated storage) with zero change in process parameters over time. NT-350HT allows the parts builder to efficiently build large out-of-autoclave structures with near zero voids, with minimum debulking. While NT-350HT was designed for OOA processing, it is perfectly suitable for in-auto-clave processes and other processes as well. NT-350HT is suitable for aerospace secondary and primary structures, space, satellite structures, and radomes.

The perforated film that comes with this material is necessary for the processing of this material. Do not discard this film material on arrival.

This product is 50″ wide and sold by the yard with a 5-yard minimum purchase required.

Storage & Out Life

This material can be left out of freezer storage for 12 months in ambient storage conditions (70° – 80°F). It is still recommended to keep this in a sealed bag for the cleanliness of this product.

Cure Cycles & Performances

This information can be found throughout the TDS available.

- Curing Schedule is meant to be a guide only and is subject to local conditions.

- To avoid exotherm particular care must be taken with thick laminates.

Health and Safety

This material contains epoxy resin which can cause allergic reactions with skin contact and must avoid repeated and prolonged skin contact.

Please refer to the product Safety Data Sheet before using this material. The following precautions must be taken when using epoxy resin prepregs:

• Overalls must be worn.

• Impervious gloves must be worn.

Custom Prepreg Options

We can have almost any of our fabrics pre-impregnated for you. Please email us for more details. We have systems in our PREG3xx series that can cure at various temps from 86° F to 275° F with safe service temps of over 600° F. We can do a max width of 60″ and also offer toughened systems. Lead times are usually 3-4 weeks for custom prepreg. We can do single-sided or double-sided prepreg, vary the resin % in the cloth, and vary the tack level of the material. Options are endless.

We take care in shipping our items and we will never fold the fabric. Our fabric is always rolled onto a tube to prevent distortion of the weave.

Reviews

There are no reviews yet.