Description

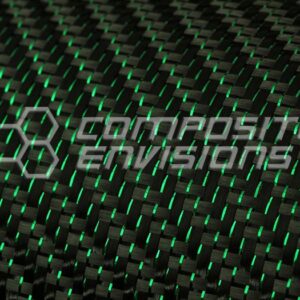

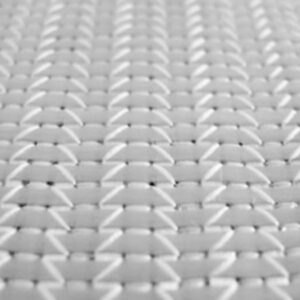

2nd Quality with waste strands throughout the material. The material is a hybrid of carbon fiber and Kevlar. This fabric has a width of 50″, tow size of 3k and is woven in a 2×2 dual twill weave. This material gives a very unique appearance as the colored Kevlar runs in the warp and weft direction of the fabric. This material has a higher than standard, 14×14 construction to provide a better/tighter weave structure which gives minimal gaps in the weave and better overall appearance.

To harden the raw fabric into a usable form, you will need the appropriate resin or epoxy for your project. For the colored materials, we suggest one of our resins which cure clear.

Product Description

Carbon Fiber / Aramid / Kevlar Hybrid fabrics.

This carbon fiber and aramid hybrid fabric combines the properties of both highly advanced fiber reinforcements. The carbon tow provides a very high level of strength and stiffness, while the aramid provides very good impact/abrasion/fracture resistance to the laminate layup. The aramid that is used in our cloth featuring colored aramid is DuPont Kevlar® while the natural or yellow aramid fabrics use either DuPont Kevlar or Lumat brand aramid. These fabrics are not just amazing looking cloths but combined with their unique weave patterns, they are ideal for usage in a wide variety of different applications. Many high-performance, high-impact applications can benefit from these materials such as boat building, automotive, military, racing, sporting goods and high strength paneling, just to name a few.

This material is suitable for just about any process that you would like to use. Like a simple wet-layup, or more advanced processes like vacuum infusion, vacuum bagging or RTM manufacturing processes. In addition to dry cloth, we are able to have this turned into prepreg for the advanced composite customer. This material is also highly sought after for parts that are being wrapped/skinned for just a single surface layer when trying to gain that cool composite look with an added reinforcement layer and not spending the time or money into creating tools for finished parts.

When using this material as a reinforcement in a part, you will want to use several layers of this fabric in each part. We also recommend rotating the composite layers to give the parts the same attributes in all directions. Non-structural components like body panels and covers will typically require only 1 or two layers of this cloth when combining this with other layers of reinforcement like standard carbon fiber or fiberglass fabrics.

Color Disclaimer: Due to individual user’s monitor settings, calibrations and lighting sources, the colors that appear on your screen may not be an exact representation of the actual product.

Reviews

There are no reviews yet.