Description

CE 4092 is a modified epoxy pre-impregnated system which can cure at 250°F (121°C) for one hour. CE 4092 can be supplied on any commercially available glass, Kevlar, or graphite fabric. Both sides of the fabric are pre-impregnated yielding a double sided tack material with the CE 4092 prepreg system. CE 4092 prepreg system can be used for laminating and honeycomb sandwich construction.

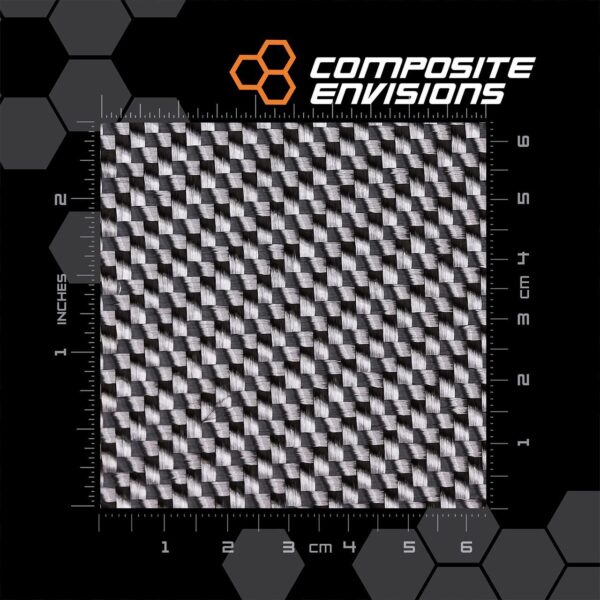

This prepreg fabric has a width of 50″, tow size of 6k and is woven in a 2×2 twill weave. This material is woven tighter than most of our competitors’ fabrics. This will help ensure a straight weave and a better looking final product.

Sold by the linear yard with a 5 yard minimum purchase required.

Cure Cycle

CE 4092 can be cured at 250°F (121°C) for one hour, however shorter cures are possible at higher temperatures.

The prepreg may be cured using either standard heat-up methods or by in-hot, out-hot press applications. A pressure of 30 psi is recommended, however pressures of 10 to 50 psi may be used.

Storage & Out Life

Store material in a contaminate free container and store at 0 degrees F for extended storage. For shorter storage time requirements store at 40 degrees F, this enables quicker stabilization times.

Application

Remove material from cold storage at least 20 hours prior to use to allow for stabilization at room temperature. Keep the material wrapped to prevent moisture from condensing on the adhesive. If details are cut and replaced into cold storage, shorter stabilization times may be used.

Cut the prepreg to size, remove the poly separator and apply to part or mold. Remove separator paper. Continue the process until the desired number of plies are obtained. Debulking is recommended after every 5 – 20 plies. The material may be debulked at temperatures up to 120°F. When lay-up is complete, the prepreg can be cured in a vacuum bag in an oven or autoclave. Apply at least 10 psi pressure and cure for one hour at 250°F.

Health and Safety

This material contains epoxy resins and amines which may cause irritation to sensitive skin. Avoid contact with eyes or skin. If contact with skin occurs, wash as soon as possible with soap and water. If contact with eyes occurs, flush with water for 15 minutes. Do not handle or use this material until the Material Safety Data Sheet has been read and understood. The user of this material is required to use the necessary protective equipment as directed by applicable state and federal laws when handling, curing, and grinding this material.

Shipping: This material should be shipped expedited airmail. Due to a short shelf life at room temp we suggest shipping this material via an expedited service such as UPS Overnight, 2-day or 3-day. These are guaranteed services. If these are chosen, we will ship the materials in the beginning of the week to ensure they do not sit in the shipping company warehouse over the weekend. We send the material with insulation and icepacks. It is suggested that you ship with 2-day airmail at a minimum. If you plan to use material within days of arrival or are OK with loosing days of shelf life, you can select any shipping method you would like, however if our minimum suggested shipping method is not chosen, we will not be held responsible for issues with material.

Custom Prepreg Options

We can have almost any of our fabrics pre-impregnated for you. Please email us for more details. We have systems that can cure at various temps from 150° F to 275° F with safe service temps of over 600° F (minimum ordered quantities may apply). We can do a max width of 60″ and also offer toughened systems. Lead times are usually 2-3 weeks for custom prepreg. We can do single side or double sided prepreg, vary the resin % in the cloth and vary the tack level of the material. Options are endless.

We take care in shipping our items and we will never fold the fabric. Our fabric is always rolled onto a tube to prevent distortion of the weave.

Reviews

There are no reviews yet.