Description

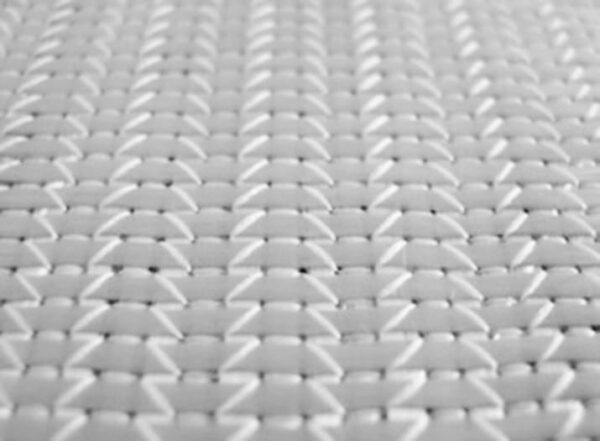

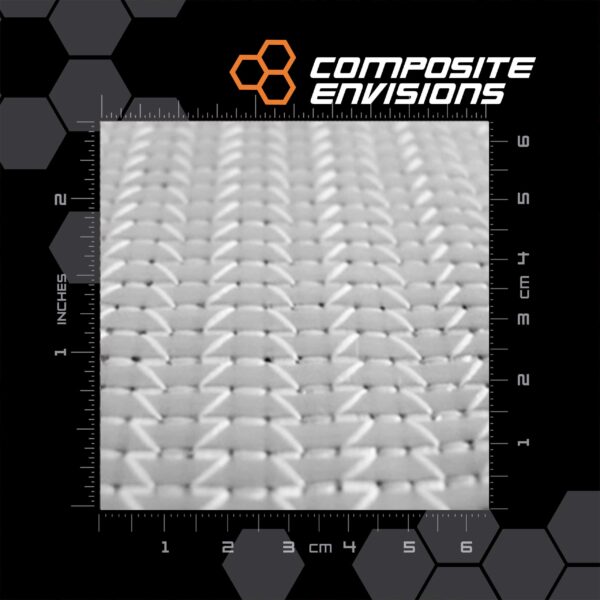

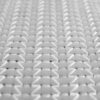

This material is great for quick buildup and high strength projects. This material contains 18oz fiberglass woven at 90 degrees. On the backside a layer of 3/4oz fiberglass mat is also attached. This material offers strength in various directions and is great for many projects. Thickness is .048″. This material was made in the USA by Knytex, a respected manufacturer in the composite industry, and will ensure you receive quality material.

To harden this material you will need to use one of our Epoxies or Resins. This fiberglass is compatible with polyester, vinyl ester and epoxy resins.

Only logged in customers who have purchased this product may leave a review.

How We Sell - Fabrics

Our fabrics are sold by the linear yard, with the exception of our samples which are a single 4"x4" (or 5"x7") piece. The unit price displayed is for 1 linear yard; all volume discounts will be automatically applied when selecting larger quantities of fabric when added to your shopping cart, as indicated in the table above with quantity discount ranges for units purchased.

Please purchase the number of linear yards that you require. When purchasing multiple yards of the same fabric, you will receive one continuous length of that material. We carefully take that material and roll it onto a cardboard core and wrap clear plastic or Kraft paper over it, making sure to keep the fabric in its first quality condition. We pride ourselves on having one of the best material handling crews possible.

Resin Consumption

Resin consumption is provided for the approximate amount of resin by weight in the final part after processing by vacuum infusion. This does not account for the resin used in the flow lines and consumables such as flow media or breather cloth. Wet-layup by hand will also have a higher resin consumption in the final part and depends on the user’s techniques. Vacuum bagging a wet layup will improve the resin content. Too much resin will cause a weaker part, not stronger. The average rule of thumb is around 45% (+/- a couple of percent). To calculate actual resin % in your part, a burn test is used. For example, you have a part weighing 100 grams, and you would burn off the resin, which would leave the fiber behind. You should have 55 grams of fiber left when your process is working correctly. Due to the variables in processing, it is hard to give an accurate amount of resin needed to purchase for making your part. However, you will have waste no matter what method is used. A suggested ratio is about 1-1.5lbs of resin per lb of fabric purchased.

Reviews

There are no reviews yet.