Description

Spread tow fabrics have practically straight fibers which result in a greater stiffness and a greater strength in compression due to reduced fiber buckling. These low crimp rate fabrics enable a higher fiber-to-resin volume ratio in composite parts. While biaxial weave fabrics provide reinforcement in two main directions, triaxial weave fabrics exhibit the same properties in every direction due to their quasi-isotropic fiber configuration.

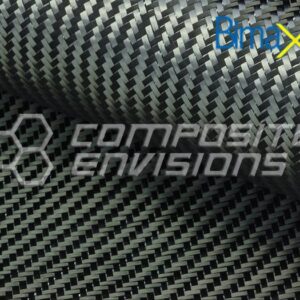

This is a fabric sample that’s available in a 4″x4″ size.

Lighter. Spread tow carbon fiber fabrics are woven from fiber tows that are spread into thin tapes. Tape area density is inversely proportional to spreading width. Whereas the lightest traditional carbon fiber fabrics weight 90 gsm, spread tow fabrics can achieve densities as low as 40 gsm.

Straighter fibers. Compared with traditional reinforcement fabrics, spread tow fabrics have practically straight carbon fibers. Straight fibers have a higher rigidity in tension than undulated fibers and result in a stiffer fabric. Since their buckling is not initiated, straight fibers also have a better resistance to compressive stress.

Higher fiber-to-matrix ratio. Since spread tow carbon fiber fabrics are extremely flat, they require less resin than traditional fabrics to be impregnated. This results in composites with a higher fiber-to-matrix volume ratio and overall better mechanical performances.

Because they have practically straight fibers and a woven structure, spread tow carbon fiber fabrics combine the stiffness of non-crimp laminates and the reduced de-lamination risks of woven fabrics.

Triaxial weaves such as the dense triaxial weave or the light triaxial weave have a [0°/ 60°/-60°] fiber orientation. Taking the modulus of a unidirectional composite as a reference unit, a triaxial weave composite exhibits a constant modulus of 0.375 regardless of the direction. In particular, as a woven [0°/ 60°/-60°] quasi-isotropic laminate, a dense triaxial weave fabric is a versatile reinforcement.

Impregnation tips

Use of a spray adhesive

Place the fabric on a clean surface. Adjust the tapes if some are misplaced. Once the appearance is okay, use a spray adhesive to immobilize the fibers. Turn the fabric upside down on the mold surface.

OR

Place the fabric onto the mold, adjust the tapes if some are misplaced. Once the appearance is okay, use a spray adhesive to immobilize the fibers.

Some spray adhesives are designed to dissolve in the resin so that it does not interfere with the curing process.

Impregnation through a more friction-resistant fabric during hand lay up

Place the spread tow fabric on the mold surface. Adjust the tapes if some are misplaced. Once the appearance is okay, on top of the fabric, place another layer of more friction resistant fabric such as a non spread tow one e.g. a very light glass fabric, a peel ply etc. Put the resin on the laminate and spread it to impregnate both fabrics.

Resin flow control during vacuum infusion

In order to attenuate a displacement of the fibers, it is recommended to limit resin flowing inside the spread tow fabric regarding in-plane directions. The resin should rather come from the top, perpendicularly to the fabric. A thick infusion mesh can help.

Tacky gel coat

Place the fabric on a tacky surface such as a gel coat and gently press it to optimize the fibers adherence to the surface.

Reviews

There are no reviews yet.