Description

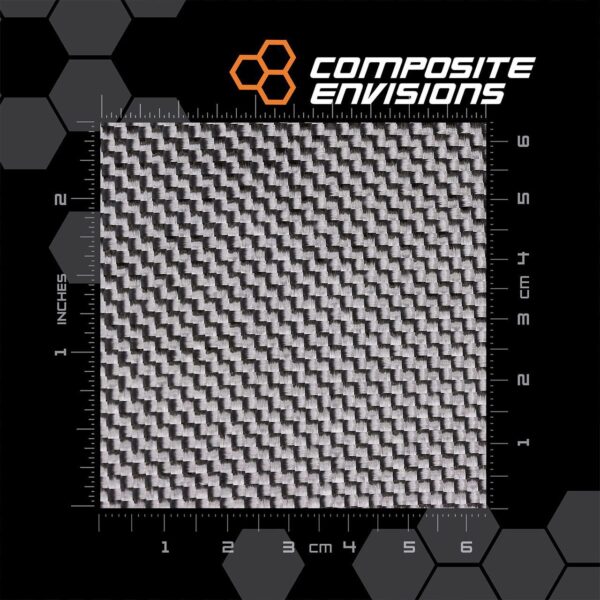

This fabric has a special process applied to it that spreads out the fibers to create a fabric with over 99% fiber coverage, thus eliminating nearly all gaps in the weave of the fabric. Not only is this is one of the nicest looking materials we offer, but this Primetex finish also makes a more even part with minimal excess resin deposits. This fabric is perfect for manufacturing parts and also is the same style of fabric used in the high dollar OEM carbon fiber parts. This material gives the best cosmetic appearance available while remaining easily drapeable. Material is woven here in the USA to ensure high quality standards. Fabric is produced by Hexcel.

PrimeTex®

PrimeTex® is a range of carbon fabrics which have been processed for a smooth, closed weave and uniform cosmetic appearance. The fiber tows are spread in both the warp and weft direction for unique aesthetic appeal. PrimeTex® fabrics are more uniform as the filaments in each tow are spread out creating a thinner and more closely woven fabric that provides better mechanicals and less porosity in a composite. It can also be used to lower the mass in a composite where lighter weight is the key characteristic.

- Patented technology with fibers spread in both the warp and weft direction

- PrimeTex® spreading process improves closure factor compared to conventional weaving process (depending on carbon tow and Fabric Areal Weight)

- Use of higher K tow for a given Fabric Areal Weight (FAW)

- Weight saving: Up to 20% at affordable cost when replacing HS3K by IM12K

- Uniform weave and gap-free structure: porosity reduced / less labor for part finishing

- Excellent water tightness when used in honeycomb sandwich structures

- Laminate mechanical properties maintained after spreading process with reduced variability thanks to homogeneous resin/fiber distribution

Typical Applications:

- Aircraft and helicopter sandwich structures and thin monolithic parts

- UAV/Light Aircraft market targeted by cost to weight

- Automotive structures (e.g. BMW roof)

- Sports equipment (e.g. skis)

Primetex Technology Information

To harden the raw fabric into a usable form, you will need the appropriate resin or epoxy for your project.

Reviews

There are no reviews yet.