Description

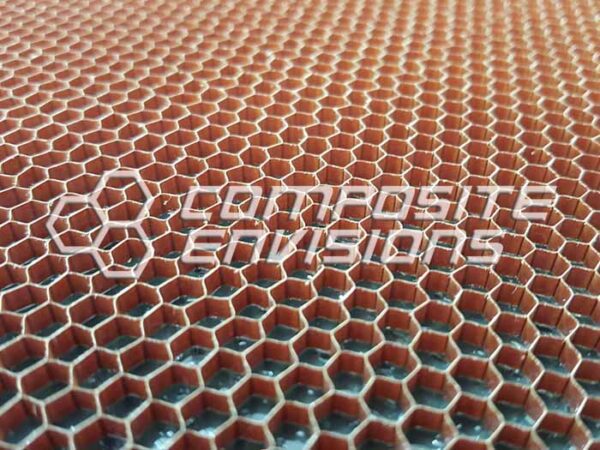

1/8 cell size, 3.0 lbs/ft3 density

*Note: Oversized Shipping Charges May Apply.

Due to the large size of these panels shipping weight is based on dimensional weight, not actual weight which results in a shipping weight that is greater than the actual weight of the product.

This material is available in 0.125″, 0.25″, 0.375″, 0.5″, 0.75″ and 1″ Thicknesses.

Nomex honeycomb composites helps provide lightweight strength, stiffness, toughness, corrosion resistance and other attributes, which bring high value-in-use to industries such as mass transportation, construction, and marine shipping.

For more than 30 years, the transportation industry has embraced honeycomb composite made with Nomex for its excellent strength-to-weight ratio, which helps to provide vital cost-effective benefits like energy savings and payload increases. Stiff, thin Nomex sheet structures are used to help make strong, yet lightweight, honeycomb sandwich composite found in aircraft parts such flooring panels, interior walls, storage bins, exterior control surfaces, engine nacelles, and helicopter blades and tail booms. Nomex honeycomb composites are also used in the construction of boats to help provide buoyancy that enhances speed.

Nomex Honeycomb is a lightweight, high strength, nonmetallic honeycomb core material manufactured from aramid fiber paper with the typical hexangular cell shape. After the honeycomb is formed, it is coated with a heat resistant phenolic resin to increase its strength and thermal properties. It exhibits a high strength-to-weight ratio, exceptional stiffness, and is very bondable.

Nomex Honeycomb is becoming increasingly used in high-performance, non-aerospace components due to its high mechanical properties, low density and good long-term stability. It is ideal for any structure which requires corrosion resistance and thermal insulation.

Reviews

There are no reviews yet.