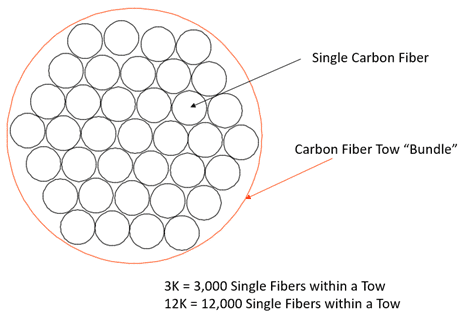

One thing that is very important in composite structures is that the laminates are completely “wet-out”. This means that each of the carbon fibers are surrounded or enclosed by a matrix of resin. This is usually consumed by the area inside of the orange area inside a tow bundle. When using a 3K Carbon or other fabric, it is easier for the resin to surround the fibers and wet through the fabric layer(s) completely. There is simply less surface area that the resin must fill. 12K Carbon Fibers, on the other hand, may take an additional 4x the amount of resin to properly wet out fibers.

Importance: If a laminate is not completely wet out, the composite part is not worth its weight in paper. In a composite structure, the fibers do most of the work. However, the resin holds the fibers together, enabling the composite system to carry loads within the tow and composite structure. Proper resin amounts and wet out are imperative to high performance composites.

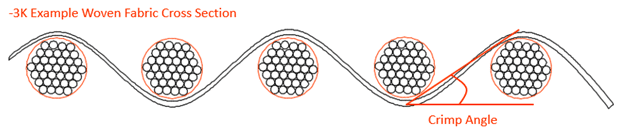

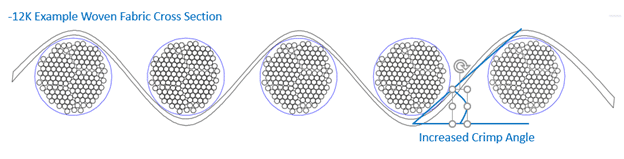

Even when a composite structure is wet out, there are additional advantages when using more thin layers of 3K over that of a 12K. A characteristic of Carbon Fiber or other fabric weaves or twills is called a “Crimp-Angle”. (Shown below) A crimp angle is the angle in which fibers are drawn back and forth as a weave is made. Unidirectional fibers have no crimp angles but woven fabrics especially, are susceptible these high angles. The higher the crimp angle, the weaker a part may become over time. The tighter woven fabrics are packed in, additional stresses are placed upon the fibers as they are subjected to loading. Over time these high angles may lead to fabrics weakening over time. A 3K Woven fabric is inherently going to have less crimp angle than that of a comparable 12K woven fabric. The fact is, as 12K woven fabrics are denser, the crimp angles are then increased. This increase may or may not affect the final use of the composite, this is dependent of the products end use. Over time,

laminates subjected to repeated loading benefit by having a woven fabric that has less crimp angle such as that of a 3k fabric compared to that of a 12k fabric. For parts used for more visual purposes on simple contours, a 3K woven fabric would have no advantage over a 12K.

With flat or simple parts with little to no curvature and that are not subject to repeated loadings, there is not as much of an advantage of using a 3K woven fiber over that of 12K. In fact, the advantage of using fewer layers of 12K over additional layers of 3K lies in fabricating simple parts from woven fabrics. When parts are going over a range of contours with complex ply shapes, the value of thinner layers lies in the ability to layup fabric plys to a higher degree of laminate quality and overall performance properties over time. For the same reason there are twill and type woven fabrics that make layup over contours more achievable and keep the fibers arranged in a way that optimizes their performance.