Vacuum Pressure, one of the most used “tools” of the composite trade. Its importance is applying consistent equal pressure upon a layup surface. This concept is proven to aid bringing out the highest quality in any composite laminate. Achieving the best in fiber / resin ratios, material properties, and surface finish are all complimented by its application, no matter the process. To some in the industry, Vacuum Bagging is an art of composite fabrication. Prepreg, infusion and wet layups can all benefit from the proper application of a vacuum pressure under a carefully prepared, quality, sealed bag. But how does one know what type of equipment is needed, what is the max achievable vacuum in a general elevation, or what type of pump(s) work well in composite processes? We’ll discuss this plus a few tips on getting the most out of a given setup.

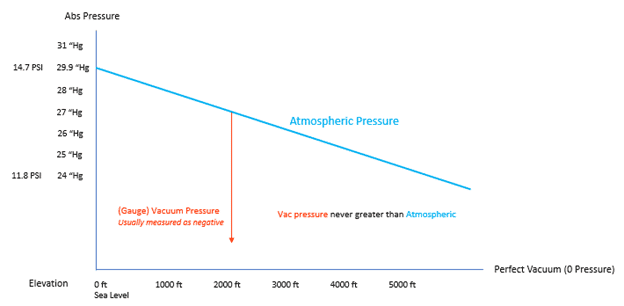

Basically, at sea level, the max vacuum one can achieve under a vacuum bag is ~29.5. However, this is under near perfect conditions. As one goes to higher elevations the max achievable vacuum is lower as the atmospheric pressure is lower. As a rule of thumb, for every 500 feet above sea level one goes, atmospheric pressure goes down by 0.5 “Hg. That means the max vacuum one can achieve goes down as well. In common practices, subtracting 1 “Hg from the total will give one something to shoot for with an optimal pump setup.

The type pump being used for composites bagging will have implications on how much vacuum pressure that may be applied on a part under a bag. In respect for what one will pay for fabric and resin, an investment into a quality vacuum pump will make life in fabricating composites much easier. Selection of these pumps may depend heavily on the size of the layup & cure process that is being used.

For Wet layups, it is a good idea to have a pump that can operate at a range of vacuum levels. While most vacuum pumps can pull a certain amount of pressure, not all types like to be run in a limited or regulated fashion. Oil-less pumps such as a dry rotary vane or diaphragm type pumps work well in these type situations as wet layups may require a lower pressure to keep resin in the part or control pressures with parts with core embedded. Oil lubricated vacuum pumps could be used but would not be needed for wet layups.

Infusion processes will likely need a higher setting for maximum vacuum. Fabric material within the layup will need to be held tightly against the mold surface. If it is a larger part, pressure regulation may become a factor as a lower pressure may be utilized after the resin is fully introduced to the part. For smaller infusion jobs, a diaphragm pump would work well with a regulated system. For larger infusions, a Rotary vane type vacuum pump may work best.

Prepregs call for the highest vacuum levels needed. Most prepregs need at least 24 “Hg to achieve best material properties. The easy part of prepregs is that once the bag is down, there is no need for a high CFM rating. As once the bag is drawn down, there is not anything to require a pressure variation inside a quality sealed bag. Oil lubricated rotary vane type pumps work well with prepreg processes as oil lubricated pumps tend to have higher achievable max vacuum levels.

In composites, one may hear of Cubic Feet Per Minute (CFM) and how it categorizes vacuum pumps. CFM implicates how much air can be drawn out under a given bag in a certain amount of time. On the surface, a vacuum pump with a larger CFM capacity would yield better on larger parts. As higher CFM pumps will pull more air out quicker, drawing down vacuum faster than that of a lower one. But this isn’t always needed. When it comes to quality, vacuum pressure is key. Not necessarily how quickly a bag is drawn down or that a “vacuum pump” even pulls out the massive amount of air space. There are a few different ways to get by with lower CFM pumps and keep a high-quality part in a timely fashion. The biggest thing is to mitigate the amount of excess air inside a bag.

One can do this by leaving a small gap in the bag seal and push the air out of the hole, like folding a tent up to take the air out. Another is to use a simple shop vac system to pull the initial air from the part and then apply the vacuum pressure using the vacuum pump. Most often 95% of the air inside of the bag can be removed with the shop vac on most bagged parts. A shop vac system has a high capacity from CFM, for moving air, but does not generally create much pressure at all. This high CFM makes it a likely candidate to use as many people use shop vac systems already at home.