Thermocouples are simply a composite part’s thermometer and most often referred to as TCs. As a composite part is cured with the application of heat, a thermocouple (TC) will tell when that part has reached its cure temperature parameters. Thermocouples can be used to log historical temperature data but most often provide real time cure cycle data while composite laminates are curing. In many applications, thermocouples can be and are used to drive composite cure cycles, dependent on the logic or programming created within the oven or autoclave.

Thermocouples can be arranged very simply to only monitor temps in a given cure cycle but are easily capable to monitor and drive every temperature aspect of a cure cycle, including but not limited to controlling cure characteristics in a multitude of laminate temperatures, whether it be the surface, mid or at the tool surface of a given laminate. TCs may also be placed within a tool, measuring how much tools may heat up, gathering this additional pertinent data can tell how the temperature and thermal expansion may affect dimensional characteristics within the tool. TCs are wonderful tools in the composite industry. In the sections below, some of the most effective ways to use them will be described.

A plug & play system (Instrument) can range from less than 50$ to upwards of $500 dependent on the needs of data logging, calibration, and precision needed. Many of the Instruments provide a means in which data can be seen in real-time. Most instruments will also allow for data to be collected, placed into a file, and ran for charts / graphing purposes of the cure cycle or any other pertinent temperature collection application. Some write this data onto an SD card for such purposes, but wireless options are available for sending information from the instrument to a computer. Instruments can be set to record temperatures at different intervals, according to how they are setup.

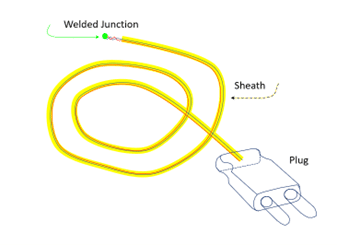

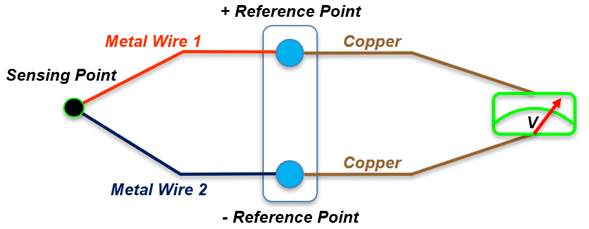

At the end of a TC, (2) wires are joined. These (2) wires are dissimilar metals (alloys). As heated, the temperature difference drives a voltage change from the sensing point to the (2) reference points. Each reference point is met by a copper wire and measured for the voltage difference. The difference of in these voltages are dependent on the temperature it is exposed to. Upon the TC being carefully calibrated, it will precisely measure the temperature based on this voltage difference. *

TCs come in various types based on the metals used within the TC sheath. Most commonly, J-Type and K-Type thermocouples are used in most composite fabrication practices.

*For more information on technical information on TCs or for a more in-depth physics lesson, research the “Seebeck effect”.

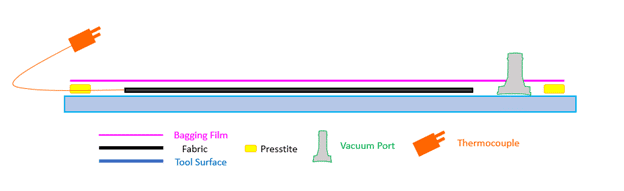

In a composite part just placed into an autoclave or oven, the general ambient air temperature does not equate to the part temperature or more importantly, the resin temperature needed for throughout the laminate part to cure. General ambient oven temperatures will get the part to its needed cure temperature, eventually. How long that truly takes will be a mystery without TCs. It takes time for the resin to heat up enclosed within a bagging scheme full of breather, separating film, and then considering additional laminate thickness, and even going as far as different bagging films and their respective materials. If one goes as far to place TCs at the top, middle and tool side of a curing part, there will be noticeable differences in the temperatures as the mold and part are heated. The tool will heat differently that the part. Sometimes these temperature differences can be up to ~20ºF. Summed up, if parts are being ran at elevated temperatures, MAKE THERMAL MAP OF THE TOOLS AND CURING PART(S) WITHIN THEM. Being able to monitor these temperature differences and allowing the full part to cure will account for achieving a quality part. In simple terms, if one is putting the time, money, and effort into making quality elevated temperature laminates, TCs are simply a must for any oven application in composites, especially for first time parts. Once parts have been “established” and data has been collected for cure parameters and times needed, they may not be as critical of an issue on each cure cycle. However, that initial data collection on tooling and composite laminate alike is critical. TCs provide the means for the data to be collected.

Thermocouples are one of the most used devices in composite fabrication. For quality control, a resin’s cure temperature must usually be reached and held for a certain amount of time to achieve a quality laminate. Being able to see cure parameters in real-time is critical to achieving desired properties of a resin and fabric combination. The “best” placement for a TC sensor is IN the actual part. Usually mid thickness at the part’s edge will suffice. (This is another reason to leave a little extra material beyond the final part’s scribe line.) The goal is to embed the TC sensor point into the part by between ~1/4” & 1/2”. Historical composite data points to say that this is usually one of the lagging, or slowest temperature recording points to reach the desired cure temperature parameters, making it a good choice for placement. (Ensuring proper cure temperatures) TCs are not limited to just the part though. TCs embedded into the tool, near the layup surface of the part are often found to

provide the thermal map of the tool in addition to close temperatures of the composite just on the other side of the mold. It would be optimal if you could run a TC down the mold surface TC wire impression probably wouldn’t look good on a shiny new spoiler.

Thermocouple arrangement may seem complicated on the surface but below are some rules of thumb for the logistics of TCs:

Be very careful with the welded joint / sensing point. If it is to break off, the TC will not work or read correctly. To keep TCs in long lasting proper working order, keep TCs organized, rolled up in coils, and stored within a sturdy small box to prevent unneeded wear and tear.

If one does happen to break, there are a couple options. 1) Throw the TC away, they are inexpensive. 2) Get a small Thermocouple welder, if the process calls for a lot of thermocouples, this is a good idea. For small scale operations, many times just discard. For information on cure parameters of a resin, always reference the resin’s Technical Data Sheet (TDS).