Often fabricators show or even market a composite part that is beautiful, accompanied by a surface layer that has been sanded, prepped, top-coated, and polished to a mirror finish. Ever wondered what is actually inside that composite part? Was the part fabricated out of all carbon fiber? Or was the part just a single top layer of carbon fiber to get the carbon fiber look while the structure is reinforced with fiberglass. Apart from using sound scanning measures, we’ll discuss a few ways of telling the difference between actual carbon fiber fabricated parts and fiberglass parts skinned with carbon fiber. Some of these are easy dead visual giveaways while some may require a drill or a nose for.

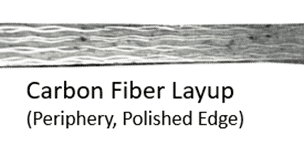

One quick way to tell if a part is real carbon fiber or just skinned is to check the laminate stack-up from the edge of the part. If one suspects a part is made from fiberglass, check an edge along the periphery of the part. (Is the part edge painted black? This may be a sign of a covering a fiberglass layup.) Part edges may indicate a laminate structure by its color. Look for a single black layer, or ply, of carbon fiber but the structural layers are usually a different color for a fiberglass layup. This is dependent on the resin used because fiberglass is opaque (transparent). Likely colors may be a greenish, clear, red tint. There is the possibility of using black resin which we will discuss further down.

Another way to tell if a part was made from fiberglass is by visually inspecting both sides of the part. While one side may show a glamourous carbon fabric, does the other side look the exact same? Is it the same fabric? Is it painted? Chop Strand Mat (CSM) fiberglass has its own visual indication that sets it apart from most any other fabric source available. Even when paired with a colored or pigmented resin, CSM stands out in any part, a cluster of non-woven randomized fibers layered for a fabric. If this is evident in any color arrangement, the part has fiberglass in it.

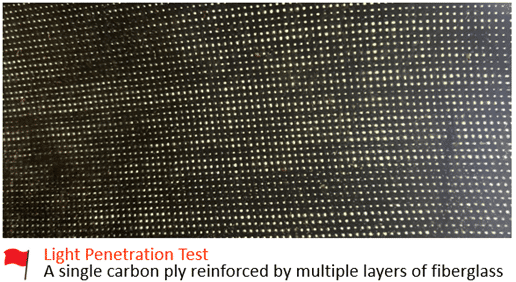

There are also visual indications for parts made from Fiberglass Fabrics over just CSM. These are a little less obvious. Fiberglass fabrics may look the same as carbon fiber parts from the surface, even up close, however, they differ in opacity (transparency) than complete Carbon Fiber Layups. For example, a part with multiple layers of carbon fiber will not allow light to penetrate through the part. However, a single layer of carbon paired with multiple layers of fiberglass will allow for light penetration through the part. A quick test may show the result. If the glass surface is painted, remove the paint by lightly sanding and check again.

90% of the time, a fiberglass part will be evident through the above tests, but if there is still doubt, one can drill a hole through the part. This would be considered a destructive test if the part would not otherwise be drilled through. The test may be very indicative of material used. While drilling a small hole look for the dust color. Black dust is evidently carbon while a whitish color is representative of fiberglass. Even with pigmented or black resin, the fiberglass will still be white. There is also a “smell” test. While drilling or trimming a part there is a difference in smell between the materials. Remember to always wear respirator PPE when cutting or drilling composite laminates, the dust may be smelled without harmful dust exposure. If one has spent any time cutting fiberglass or carbon, there is a discernible difference in the smell of these fabrics or materials.