So a car hood comes out of the mold. It looks great. But how are you going to mount it? You can’t just weld on some nuts, fittings, bolts and just call it a day can you? Composites don’t take to kindly to that kind of heat. One probably doesn’t want to just drill a hole all the way through a newly cured laminate surface just to mount the hood either. Is there an easier more effective way? Of course. Here were going to answer some questions behind composite assembly and how it may influence your next composite design. Well use a car hood as an example to show what are some of the most common ways of mounting composite laminates to an array of structures. In addition, well cover some commonly used tools used to assemble composite structures such as nutplates, studs, rivets, or inserts.

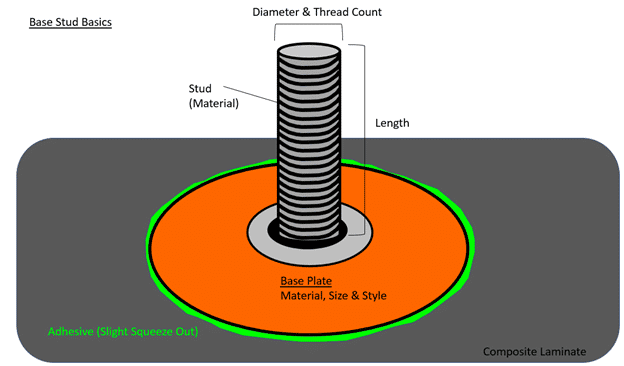

Need a bolt or stud to be placed into a laminate part without even drilling a hole? A “base stud” is commonly used on laminate surfaces by secondary bonding application as needed. Simply a stud or bolt attached to a base for bonding. These small pieces make joining composite laminates into assemblies possible and much cleaner than drilling holes through a part. There are many variations of base or bonding studs used across the composite industry. Many types of these base studs come supplied with installation fixtures that help effectively and accurately place the stud exactly where it is needed. They are often available in various thread sizes and lengths dependent on the need. (Make sure to note the sizes needed before buying). On a car hood for example, they may be placed onto the laminate surface to provide connection with the hinge assemblies on each side of the vehicle where the hood would mount nearest the windshield.

Base studs come in different base materials and studs to accommodate factors such as galvanic corrosion in carbon fiber parts or to match a composite part’s CTEs if a laminate will be exposed to elevated temperatures. An array of base trim styles are used to accommodate any fitment / placement issues a part may present. Base studs may be placed as part of composite molding process but most commonly are part of secondary bonding applications. Many base stud variations are coined “click studs” as the locating tool aids in a simple click type application effectively positioning the base stud.

Important notes on application & selection:

Most of the time, especially with modern vehicles, the latching mechanism of a hood is an assembly that can be purchased online or in auto parts store. This purchased assembly can either be secondarily bonded to the inside of the hood structure or be drilled and bolted to an internal stock skeleton of the hood assembly. This is dependent on the design of the hood.

No latch assembly? No problem.

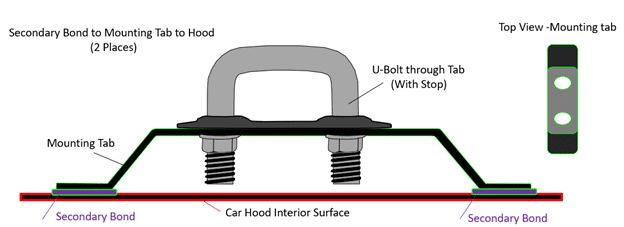

If the hood doesn’t come with “stock” hinge assemblies and there is just a U-Shape Bolt that needs to be placed, there are still simple solutions out there. Though there may not be a clear-cut solution and variation always occurs, consider the above “mounting tab” solution. This process may involve a little creativity and ingenuity but is doable. This may involve modifying a few things and some trial and error to get the absolute perfect fit in means of height and placement.

First, fabricate a small mounting tab from some extra material from a prior layup, it may not have to be perfect. The goal is to have something to allow for the U bolt to seat into yet provide enough area to provide a good secondary bond. This “mounting tab” ensures no holes must be drilled into the hood laminate but are instead applied in the mounting tab.

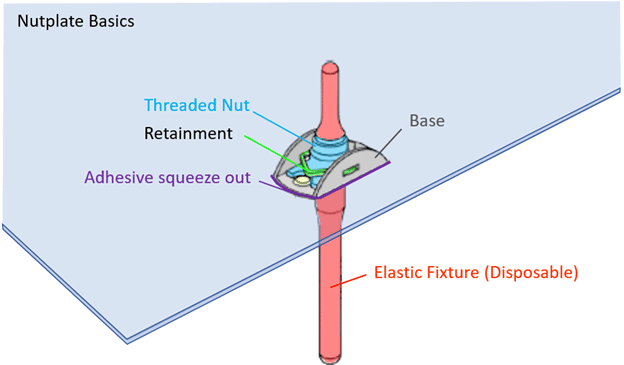

Nutplates are coined as simple as they are pronounced. Used extensively throughout the aerospace industry, a nutplate is a locking and / or floating nut, plated for secondary bonding to a composite substrate. A nutplate is bonded or riveted to a composite surface on the inside of a joint to be attached to an adjoining laminate or surface by a screw or bolt. Nutplates come in various sizes, material types, and a seemingly infinite number of designs. Riveted or rivet-less base options are available and are often applied by secondary bonding using a selected adhesive. Some nutplates allow for a degree of forgiveness in assembly processes as many can move the actual nut’s placement. One useful variation of nutplate is offered as a “clip nut”. These types of composite nutting provide easier removal

and replacement options to peripheries of composite surfaces where parts are likely to be joined. The variation in nutplates range from the above options to options as simple as nut welded to a plate. They can also be applied during the lamination process in layup. Whatever the choice may be, careful selection and research should be practiced ensuring the right nutplate(s) are selected for the job at hand.

Inserts are extensively throughout the industry inside core areas to provide strong joints to mating composites with sandwich structures. Inserts are effectively nuts placed and fixed into core structures. There are various inserts that can be placed into composite sandwich structures. These are defined by the depth the inserts go into a sandwich structure. Some go all the way through the laminate, some go through the initial face-sheet, through the core but stop at the bottom face, and others that just go through the core partially. There are many types of inserts that can be placed. Two main types are “potted” and “plug & sleeve” inserts. “Potted” inserts a generally provide a stronger bond for the part but “plug & sleeve” or “press fit” type inserts offer quicker and easier installation.

This does not say that you cannot just clean some core out and epoxy in a nut to the core, this has been done and may work for some assemblies. However, Inserts are used because they are specifically designed for high bonding strengths to composite sandwich structures.

Rivets are probably the most used joining method in composites. Although bonding composites together with adhesive may yield a stronger more effective bond, rivets have a long history of holding various materials and assemblies together of all material types. They are simple to install and are very predictable in terms of their strength and longevity in composite structures. The tools required for riveting are generally inexpensive and for the “DIY” application are very useful.