Description

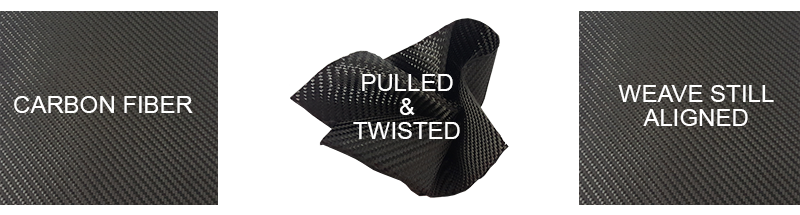

This fabric has a tow size of 3k and is woven in a 2×2 twill weave. This is the most widely used weave pattern across multiple industries. This material is woven tighter than most of our competitors’ fabrics. This will help ensure a straight weave and a better looking final product. This material has been Stabilized using our EXCLUSIVE Web-Lock Stabilization Technology.

First Quality Remnants:

First Quality Fabric Remnant Rolls are short rolls of fabric, which have no defects in them. These remnant rolls are either left over fabric from the end of a roll, or sections of fabric which were cut at the wrong length for a specific order. So instead of discarding the short roll, we package it up and sell it as a First Quality Remnant Roll. These First Quality Remnant Rolls are sold at 20% off of the retail price of that fabric.

Second Quality Remnants:

Second Quality Fabric Remnant Rolls are short rolls of fabric, which have a defect in the woven fabric in them. These remnant rolls are cut out of the standard fabrics we sell, but from sections of the rolls that have some defects in them. These defects make them not good to use if you want to make cosmetic parts, which have perfect woven fabric in them, but can be used as the inner layers of your parts, or if you are making small parts and can cut around the defects. These Second Quality Remnant Rolls are sold at 25% off of the retail price of that fabric.

All remnant rolls are rounded DOWN to the nearest ½ yard. So a remnant listed as 0.5 yards may actually be between 18” and 35” in length and a remnant listed at 2.0 yards may actually be between 72” and 89” in length.

Web-Lock is a fabric stabilization process that is achieved by applying high heat and pressure to lock every filament of fabric together, ensuring perfect cosmetic and structural symmetry. Currently, this process is ONLY offered by Composite Envisions. You may have seen or tried stabilized fabrics in the past, but we’ve found that these existing products can often be too stiff to work with, require large volume orders with high costs, or simply aren’t available in the fabric or time frame needed. All these reasons lead us to one solution – Web-Lock. Web-Lock is the material that we believe solves all the current problems and exceeds the finished fabric performance on all levels. Web-Lock will help you improve your ease of manufacturing, saving you time and money.

The side that has the Web-Lock on it will not make a good finish for your parts as you will still be able to see the stabilizer in a finished part. When using make sure to have the stabilized side face the non cosmetic side of your part. If you have a part that requires to have a perfect finish on both side we would recommend using two layers of this material and face the stabilized sides together.

Please Note: Web-Lock is not applied with a standard/default orientation. If you require a specific orientation of the Web-Lock to match existing/previously purchased Web-Lock fabrics please contact us so that we may apply the Web-Lock to the specifications desired.

Advantages of Web-Lock

Web-Lock is applied at Composite Envisions, allowing flexibility of coating options. Currently, Web-Lock has been applied to Carbon Fiber, Kevlar, Fiberglass and will be available on other composite fibers.

Reduce employee training for the time it takes to make quality composites.

Reduce waste as a result of less damaged cloth.

Standard heat range is 225°F/107°C. Coatings can range from 194°F/90°C to 392°F/200°C (only capable now of doing up to 248°F/120°C material)

Current version only adds .175oz/6gsm of weight to the fabric for little interference. (weights available from 4-15gsm to change performance characteristics)

No release liner required between layers of material; reduces waste, lowers cost and makes material easier to use.

Compatible with most resin systems on the market, including polyester, vinylester and epoxy resin.

Can be applied to various widths ranging from narrow tapes to 50″ wide.

Prevents fabric weave from shifting but stretches to allow the fabric to stay conformable.

Keeps fiber coverage even to avoid resin rich areas and failure points.

Produced in the USA. Our goal is to make Web-Lock the new standard for high-end composite fabrications meet your supply needs while exceeding your expectations.

To harden the raw fabric into a usable form, you will need the appropriate resin or epoxy for your project. For the colored materials, we suggest one of our resins which cure clear.

Reviews

There are no reviews yet.