Description

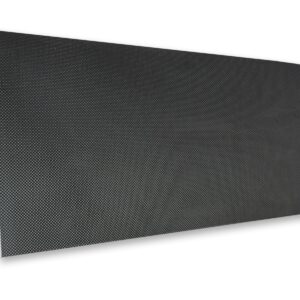

Carbon Fiber Tooling Board .25″/6.35mm made from all aerospace 3k 2×2 twill prepreg. These panels use over 25 layers of a toughened prepreg resin system that is great for impact resistance. These panels were cured at 275° F under vacuum and could be post cured additionally up to 350° F if you needed a higher temp rating. There are fine tracer yarns in the prepreg on every ft mark made from nylon and or aramid. They are barely noticeable as they are very fine but are there. These panels are better suited for general purpose applications as well as being machined down into parts. The prepreg in these panels was from an aerospace program that had strict time restrictions for using it. It is past the usable date in those programs however the epoxy still was tested and flowed well enough to make great general purpose panels that properly wet out. There are a few small pinholes in the surface of the panels but overall panels are nearly void free. We have tried to show in photos the panels and the cross section when cutting.

We have thousands of yards of prepreg available to make these panels. We are producing these panels in these thicknesses 1/8″, 1/4″, 3/8″, 1/2″, 3/4″ and 1″ and will be able to offer panels down to 1x1ft in size. We have a large stock of panels produced already and available for immediate shipment

These panels are produced right here in our shop. Due to slight variances in material, we give these tooling boards a range of /- .030 inches in thickness. These panels are typically cut by waterjet. However, due to time constraints they may be saw cut. Therefore, these panels are given a dimensional tolerance of /- .125 of an inch.

Only logged in customers who have purchased this product may leave a review.

Laminate Construction

To ensure maximum structural integrity and flatness throughout all our panels, we produce ‘balanced’ laminates for all panel thicknesses and sizes. This means that the fiber type, weight, and weave pattern are symmetrical throughout all layers of the composite stack.

Symmetric Laminates: A laminate is symmetric when the plies above and below the mid-plane mirror one another. Symmetrical layups help prevent thermal twisting.

Panels that are 1.4mm / 1/16’’ or thicker are quasi-isotropic laminates made with non-woven, no-crimp carbon fiber plies, oriented at 0º/90º/+45º/–45º. Quasi-isotropic ply orientation results in a most uniform distribution of strength and enhances both torsional and diagonal stiffness.

Cross-plied layup will yield a panel with higher structural integrity, which many applications may require. Laminate stacking and ply orientation can be adjusted for specific applications; for example, if you require greater panel strength in a particular direction, you want to avoid increasing the weight with additional plies.

The detailed lay-ups and fabric stack list can be requested for each of our panels. Please specify the panel model number when inquiring.

Epoxy: All panels are made with a high-performance epoxy resin that offers excellent mechanical functions, clarity, and improved UV stability. An elevated post-cure temperature is applied to increase the mechanical strength of the panel, resulting in a higher Tg and enhancing the inter-laminar shear strength.

Our panels are NOT clear coated or UV Protected. To ensure the panel’s longevity, we highly recommend that you apply a clear coat with UV Protection to the surfaces of panels that may be exposed to sunlight, such as DURATEC SUNSHIELD.

Panel Size and Thickness

Panels are available in select sizes starting at a minimum of 12’’x 24’’ and increasing 12” at a time in either/both directions, but not to exceed 48’’x96’’.

Examples: 12″x48″, 24″x36″, 48″x48″, 48″x60″, and 36″x96″.

Panels are cut by hand*, which may result in a dimensional tolerance of +/- .125” in either direction. Please note that panel sizes are nominal and may be supplied over-sized.

For panels larger than 24’’x 48’’, custom boxing and shipping fees may apply.

*Waterjet Cutting: To have your parts arrive at your door cut to precision, you can request your panel(s) be waterjet cut prior to shipping and simply provide a dxf/dwg cad file (additional costs apply).

Choose your desired panel size and thickness using the drop down lists at the top of the page.

Need a custom panel? Call us today for your custom panel needs: 715-842-0101

We are able to offer custom, flat panel fabrication for small runs and prototyping using most fabrics sold on our site. We can produce custom panels at a M.O.Q of 1 – 12’’x48’’ per custom selection.

Manufacturing & Lead Times

Manufacturing

Our highly technical manufacturing process and equipment allow Composite Envisions to produce composite panels to meet most custom specifications. We currently supply composite panels to numerous world-class manufacturers in various industries, including concept vehicles, motorsport racing, luxury yacht, and aerospace. Please get in touch with us to discuss your composite needs.

Lead Times

For standard panels listed on our site, lead times typically range from 7-14 business days. We stock many panels to meet customer needs, but we may need a few days to complete your order due to limitless size, thickness, and color combinations. If your order is time-sensitive, please call and check availability and expected lead times before ordering items.

Reviews

There are no reviews yet.