Description

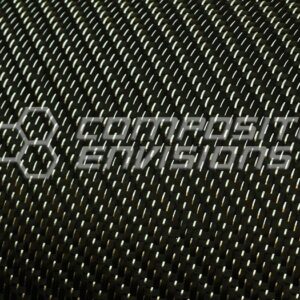

This panel has a 2×2 twill weave pattern, one of the most common weave patterns in many markets. The finished side of the panel has a classic 2×2 twill, 3K woven carbon fiber appearance and is nearly pinhole-free with a high-gloss finish. The panel’s backside showcases a matte textured ‘peel ply’ finish suitable for secondary bonding, if necessary.

Our high-strength vacuum infused composite panels are manufactured using 100% carbon fiber reinforced with a near-clear epoxy resin matrix. All composite stacks are laid by hand to ensure maximum homogenization of fiber alignment. Stacks are then vacuum infused and cured under pressure greater than 28 inches of mercury. The tool is then elevated to an optimal temperature to produce a near-perfect composite panel with high-grade mechanical properties and a class-A surface finish.

Color Disclaimer about Panels:

When Carbon Fiber/Kevlar Fabric is Vacuum Infused to make these panels, the color will darken up from the original color of the Kevlar fabric in dry form. The Blue Kevlar will turn to a Navy Blue color, the Red Kevlar will turn to a Burgundy color, the Orange Kevlar will turn to a Blood Orange color, and the yellow Kevlar (natural color) will turn to a Dijon Yellow color once they are wet out and cured.

Only logged in customers who have purchased this product may leave a review.

Remnant Panels

Our remnant vacuum-infused composite panels are manufactured using our high-quality composite fabrics reinforced with an epoxy resin matrix. All composite stacks are laid by hand to ensure maximum homogenization of fiber alignment. Stacks are then vacuum infused and cured under pressure greater than 28 inches of mercury. Though the defects may be minor in our remnant selection, they do not allow us to sell them as a premium-grade panel. Some of these remnant panels did not pass our final visual inspection or might be an excess of product from a one-time production run. These remnant panels are discounted 33% from our regular panel pricing.

Defects in these panels may consist of:

- surface scratches

- weave distortion

- pinholes

- foreign carbon particles in the surface

- hazy cosmetic surface

- outside of measurement tolerance

- dry spots

- surface finish inconsistencies

Laminate Construction

To ensure maximum structural integrity and flatness throughout all our panels, we produce ‘balanced’ laminates for all panel thicknesses and sizes. This means that the fiber type, weight, and weave pattern are symmetrical throughout all layers of the composite stack.

Symmetric Laminates: A laminate is symmetric when the plies above and below the mid-plane mirror one another. Symmetrical layups help prevent thermal twisting.

Panels that are 1.4mm / 1/16’’ or thicker are quasi-isotropic laminates made with non-woven, no-crimp carbon fiber plies, oriented at 0º/90º/+45º/–45º. Quasi-isotropic ply orientation results in a most uniform distribution of strength and enhances both torsional and diagonal stiffness.

Cross-plied layup will yield a panel with higher structural integrity, which many applications may require. Laminate stacking and ply orientation can be adjusted for specific applications; for example, if you require greater panel strength in a particular direction, you want to avoid increasing the weight with additional plies.

The detailed lay-ups and fabric stack list can be requested for each of our panels. Please specify the panel model number when inquiring.

Epoxy: All panels are made with a high-performance epoxy resin that offers excellent mechanical functions, clarity, and improved UV stability. An elevated post-cure temperature is applied to increase the mechanical strength of the panel, resulting in a higher Tg and enhancing the inter-laminar shear strength.

Our panels are NOT clear coated or UV Protected. To ensure the panel’s longevity, we highly recommend that you apply a clear coat with UV Protection to the surfaces of panels that may be exposed to sunlight, such as DURATEC SUNSHIELD.

Panel Size and Thickness

Panels are available in select sizes starting at a minimum of 12’’x 24’’ and increasing 12” at a time in either/both directions, but not to exceed 48’’x96’’.

Examples: 12″x48″, 24″x36″, 48″x48″, 48″x60″, and 36″x96″.

Panels are cut by hand*, which may result in a dimensional tolerance of +/- .125” in either direction. Please note that panel sizes are nominal and may be supplied over-sized.

For panels larger than 24’’x 48’’, custom boxing and shipping fees may apply.

*Waterjet Cutting: To have your parts arrive at your door cut to precision, you can request your panel(s) be waterjet cut prior to shipping and simply provide a dxf/dwg cad file (additional costs apply).

Choose your desired panel size and thickness using the drop down lists at the top of the page.

Need a custom panel? Call us today for your custom panel needs: 715-842-0101

We are able to offer custom, flat panel fabrication for small runs and prototyping using most fabrics sold on our site. We can produce custom panels at a M.O.Q of 1 – 12’’x48’’ per custom selection.

Reviews

There are no reviews yet.