Have a topic you’d like to see covered in our Knowledge Hub? Interested in contributing and sharing your expertise of composites’ techniques? Simply drop us a line, we’d love to hear your ideas!

| Image | Title | Content | Categories | Date |

|---|---|---|---|---|

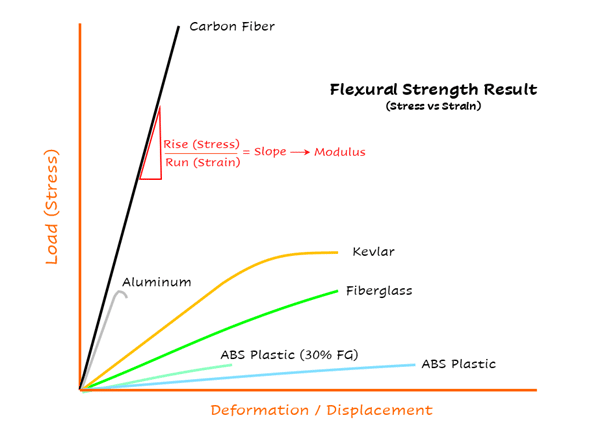

| Flexural Modulus In Composite Parts | Modulus is a measure of a composite’s resilience while it is placed under constant increasing … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 01/30/2023 |

| The History of Carbon Fiber | Electricity, Lightbulbs, Edison & Bacon Carbon Fiber was first utilized in 1860 to arc light … | Carbon Fiber, General Composite Knowledge | 12/12/2022 |

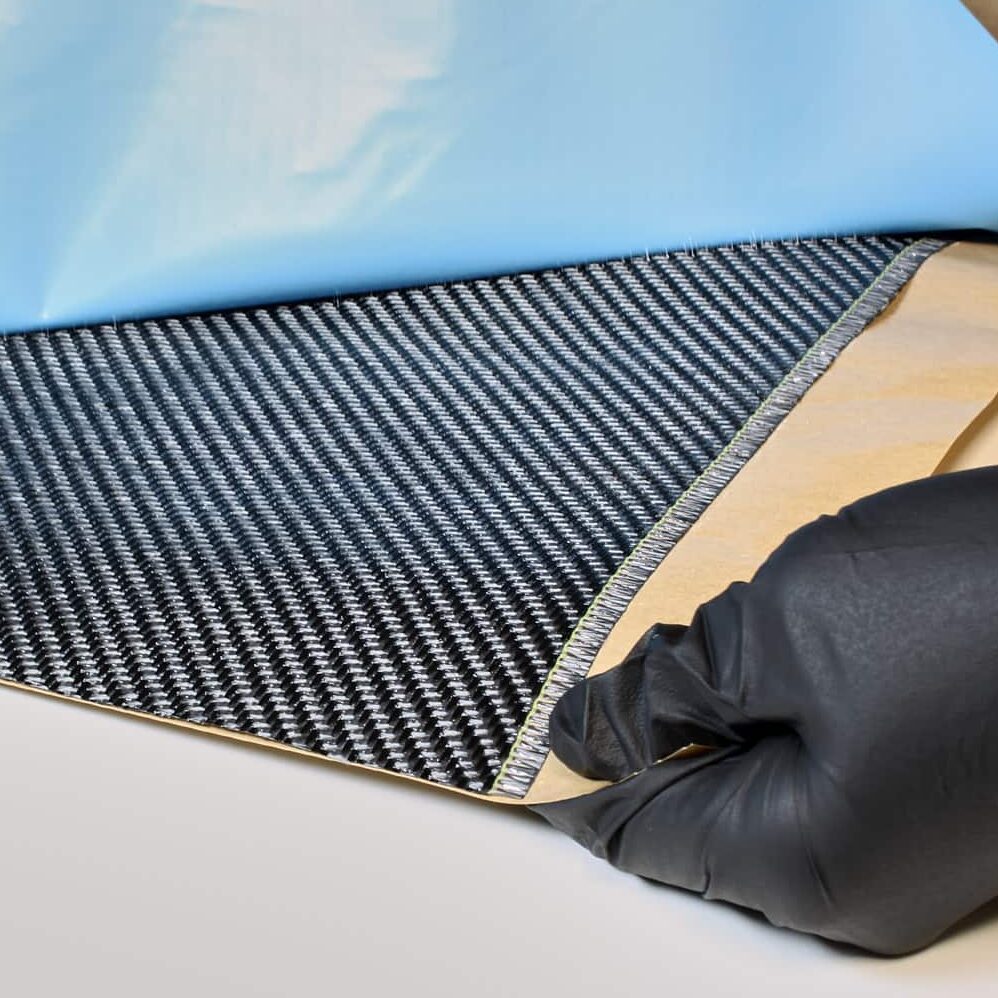

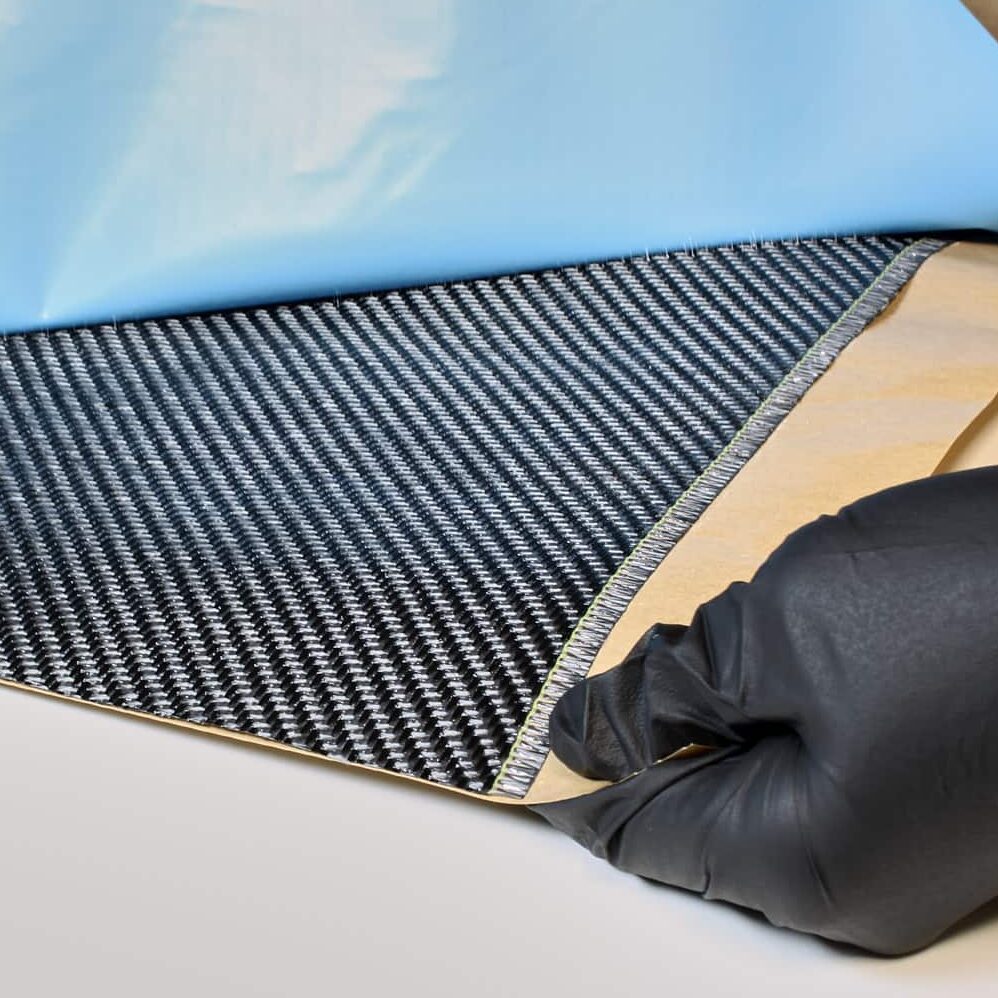

| What Is Prepreg – Explanation, Advantages and Disadvantages | “Prepreg” is broad terminology in composite fabrication used for describing fabrics that are pre-impregnated with … | Composite Reinforcements, General Composite Knowledge, Prepreg | 10/24/2022 |

| What is Filament Winding? | Filament winding is a manufacturing process using continuous strands of tow from various materials such … | General Composite Knowledge | 10/7/2022 |

| Certifications of Compliance | Certifications of Compliance (Certs) are important throughout the composite industry for achieving the utmost quality … | General Composite Knowledge | 10/7/2022 |

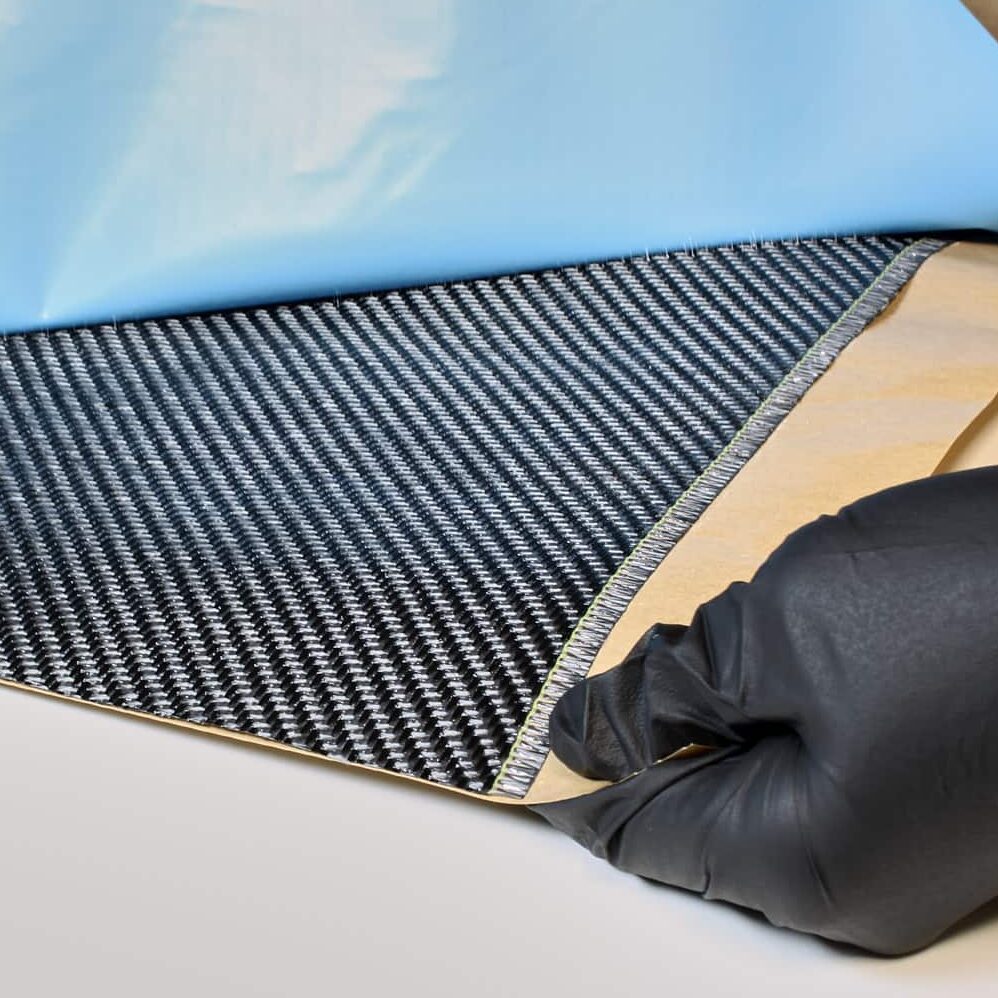

| Kitting Cloth & Your Layup Process | When it comes to layup processes, attention to each in every minuscule detail can make … | Composite Techniques, Consumables, Tips & Tricks, Vacuum Infusion | 10/7/2022 |

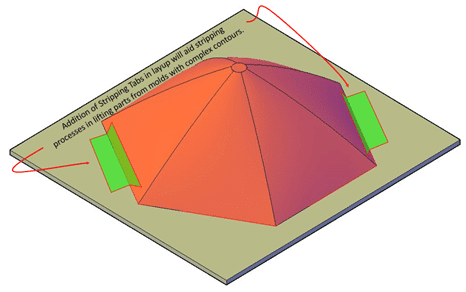

| Demolding Your Composite Part | Your part is done, now what? What do you do first when taking the part … | Composite Techniques, Mold Making, Tooling | 10/7/2022 |

| Quality Control Methods & Procedures | Large companies follow specifications given to them by a specific “customer”. Most of the time … | General Composite Knowledge, Tips & Tricks | 10/7/2022 |

| What Is Max Vacuum You Can Achieve and Does CFM Matter? | Vacuum Pressure, one of the most used “tools” of the composite trade. Its importance is … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 10/7/2022 |

| Prepreg Selection: Double Sided vs Single Sided | Prepreg selection is usually based on characteristics such as service temperature, ultimate strengths in each … | Composite Fabrics, Composite Reinforcements, General Composite Knowledge, Prepreg | 10/7/2022 |

| What To Do When Your Part Sticks In The Mold | There are various reasons as to why a part may stick to a layup mold. … | Composite Techniques, Mold Making | 10/7/2022 |

| Best Practices When Using Resins Indoors | Nearly every resin used in composites gives off some sort of smell / odor when … | Epoxy, General Composite Knowledge, Polyester, Resins, Tips & Tricks, Vinylester | 10/7/2022 |

| How To Keep Weave Straight and Aligned | Keeping a weave straight and aligned is critical in keeping a balanced layup accurate. In … | Composite Fabrics, Composite Techniques, General Composite Knowledge | 10/6/2022 |

| How To Tell The Difference Between All Carbon and Carbon Skinned vs Fiberglass Parts | Often fabricators show or even market a composite part that is beautiful, accompanied by a … | Carbon Fiber, Composite Fabrics, Fiberglass, General Composite Knowledge | 10/6/2022 |

| Carbon Fiber & Concrete Repair – An Unlikely But Very Compatible Duo | Think Carbon Fiber is just for lightweight applications reserved for aerospace, auto racing, and small … | Composite Reinforcements, Composite Techniques, General Composite Knowledge, Tips & Tricks | 10/6/2022 |

| What Temperature Rated (Tg) Resin Do I Really Need For My Job? | Glass-Liquid Transition, Glass Transition or simply “Tg” is a transition of a given polymer from … | Composite Techniques, Epoxy, Resins, Tips & Tricks | 10/6/2022 |

| Galvanic Corrosion – Carbon Fiber and Aluminum | Aluminum and Carbon Fiber are both renown for providing lightweight strength and high-performance mechanical properties … | Carbon Fiber, Composite Techniques, General Composite Knowledge | 10/6/2022 |

| Sizings – Why Do They Matter | Sizings are surface coatings on fibers that hold two major roles in making fibers effective … | Aramid, Carbon Fiber, Composite Fabrics, Composite Reinforcements, Fiberglass, General Composite Knowledge, Kevlar | 10/6/2022 |

| Carbon Fiber vs Activated Carbon For Filters | Similar in Name Only Activated carbon is a highly porous substance that attracts and holds … | Carbon Fiber, General Composite Knowledge | 10/6/2022 |

| How Well Carbon Fiber and Other Fibers Shield Radio Waves | Carbon Fiber is known widely in aerospace, sports, racing, the marine industry for its strength, … | Carbon Fiber, Composite Reinforcements, General Composite Knowledge | 10/6/2022 |

| When To Turn Off The Resin Flow During Vacuum Infusion | Vacuum Infusion can seem like a daunting task. Besides the work that goes into all … | Composite Techniques, General Composite Knowledge, Tips & Tricks, Vacuum Infusion | 10/6/2022 |

| Resin to Fiber Ratio Explained | When it comes to figuring out how much resin is needed for a given project, … | Composite Fabrics, Composite Reinforcements, Composite Techniques, Epoxy, General Composite Knowledge, Resins, Tips & Tricks | 10/6/2022 |

| Bonding Composites To Metal And Other Substrates | As part of composite processing, it becomes necessary to bond pieces of composite laminates to … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 10/5/2022 |

| What Are Location Tabs And Why Do You Use Them? | Location tabs can be used on a tool and / or part for locating & … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 10/5/2022 |

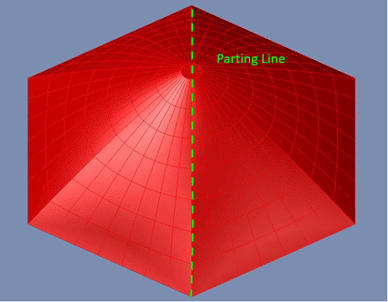

| Multiple Piece Molds – Filling The Gap | The time spent effectively preparing a plug or tooling surface will result in creating parts … | Composite Techniques, General Composite Knowledge, Mold Making | 10/5/2022 |

| Double Bagging – What Is It? | Double Bagging is a conceptual application of vacuum bagging designed in fabrication of composite laminates. … | Composite Techniques, Consumables, General Composite Knowledge, Tips & Tricks, Vacuum Infusion | 10/5/2022 |

| Benefits Of Various Substrates For Tooling | There are many options in front of any fabricator when it comes to choosing a … | Composite Techniques, General Composite Knowledge, Tooling | 10/5/2022 |

| Using Tooling Putty For Quick Mold Fabrication | Tooling putty can be one of the most effective ways of reinforcing or strengthening a … | Composite Techniques, General Composite Knowledge, Mold Making | 10/5/2022 |

| Making Cutting Templates For Molds | Ply cut templates for layups should arguably be made into a process of its own. … | Composite Fabrics, Composite Reinforcements, Composite Techniques, Peel Ply, Prepreg | 10/5/2022 |

| Breather Cloths – Why The OZ Rating Matters | Breather Cloth plays a distinct role in providing complete compaction when working in conjunction with … | Composite Techniques, Consumables, General Composite Knowledge | 09/27/2022 |

| What Does Aerospace Grade Fiber Really Mean, And Do You Need It? | “Aerospace Grade” is commonly referenced in the composite industry as establishing a basis of the … | General Composite Knowledge | 09/27/2022 |

| Peel Ply Explained and When to Use Each Style | Peel Plys, otherwise known as Release Fabrics, have many uses throughout the composite industry ranging … | Consumables, General Composite Knowledge | 09/27/2022 |

| Why Many Thin Layers Are Better Than A Few Thick Layers | When choosing a specific fabric for a given project, there is more than just the … | Composite Fabrics, Composite Reinforcements, Composite Techniques, General Composite Knowledge, Tips & Tricks | 09/12/2022 |

| Bonding Process Explained For Two Sided Parts | Secondary bonding has limitations due to the strength of the adhesive. Parts that are all … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 09/12/2022 |

| Urethane Expanding Foams | Expanding Foams are used in an infinite number of ways. Insulation, taxidermy, floatation, sculpting, and … | General Composite Knowledge, Tips & Tricks, Urethane Expanding Foams | 09/12/2022 |

| Different Bagging Films and Their Benefits | Vacuum bags are one of the most versatile tools used in the composite industry. For … | Bagging Film, Composite Techniques, General Composite Knowledge | 09/12/2022 |

| Drilling Composites – What To Look Out For | Drilling is one of the most challenging aspects in secondary processing of composite fabrication. To … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 08/30/2022 |

| How To Properly Trim Kevlar Parts | Kevlar is the lightest weight and toughest fabric type widely used in composite industry. It … | Aramid, Composite Fabrics, Composite Reinforcements, General Composite Knowledge, Kevlar, Tips & Tricks | 08/30/2022 |

| Reducing Weight In Composite Parts | As part of building anything out of composites, (and some form of competitive nature) the … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 08/30/2022 |

| Resin Additives | Resins are a unique tool for the composite industry in how they bring other materials … | Composite Techniques, General Composite Knowledge, Resins, Tips & Tricks | 08/30/2022 |

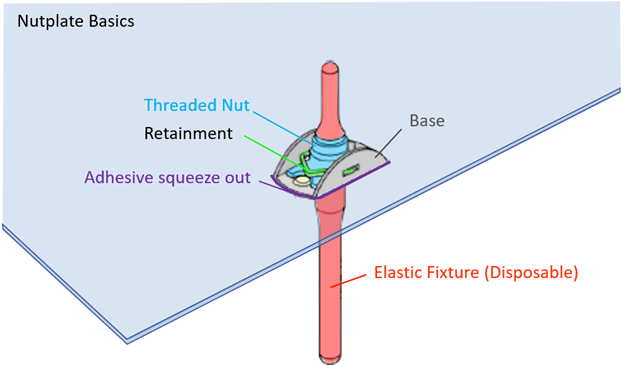

| Building Mounting Tabs Into Your Finished Parts | So a car hood comes out of the mold. It looks great. But how are … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 08/30/2022 |

| Why Post Curing Matters | Standard Air Curing Resin systems have an array of cure mechanisms ranging from room temperature … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 08/30/2022 |

| Yellowing Or Clouding Of Epoxy & How To Protect Against It | Epoxies are known for being some of the strongest and most durable resins on the … | Epoxy, General Composite Knowledge, Polyester, Resins, Vinylester | 08/24/2022 |

| Safety 101 When Working With Composites | When working with Composites, it’s important to follow some safety protocols. Before starting any project, … | General Composite Knowledge | 08/23/2022 |

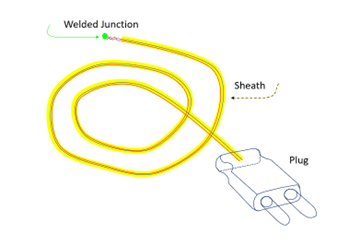

| Thermocouples – Why You Should Use Them | Thermocouples are simply a composite part’s thermometer and most often referred to as TCs. As … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 08/22/2022 |

| Spraying Clear Coat & Dealing with Pinholes | There are many ways to achieve a mirror finish for fabricated parts. The exact process … | Clear Coat, Composite Techniques, General Composite Knowledge | 08/22/2022 |

| Shelf Life & Storage of Composite Materials | “Shelf” or “Storage” life are both important characteristics in nearly all composite fabrication products. It … | Composite Fabrics, Composite Reinforcements, General Composite Knowledge, Resins, Tips & Tricks | 08/22/2022 |

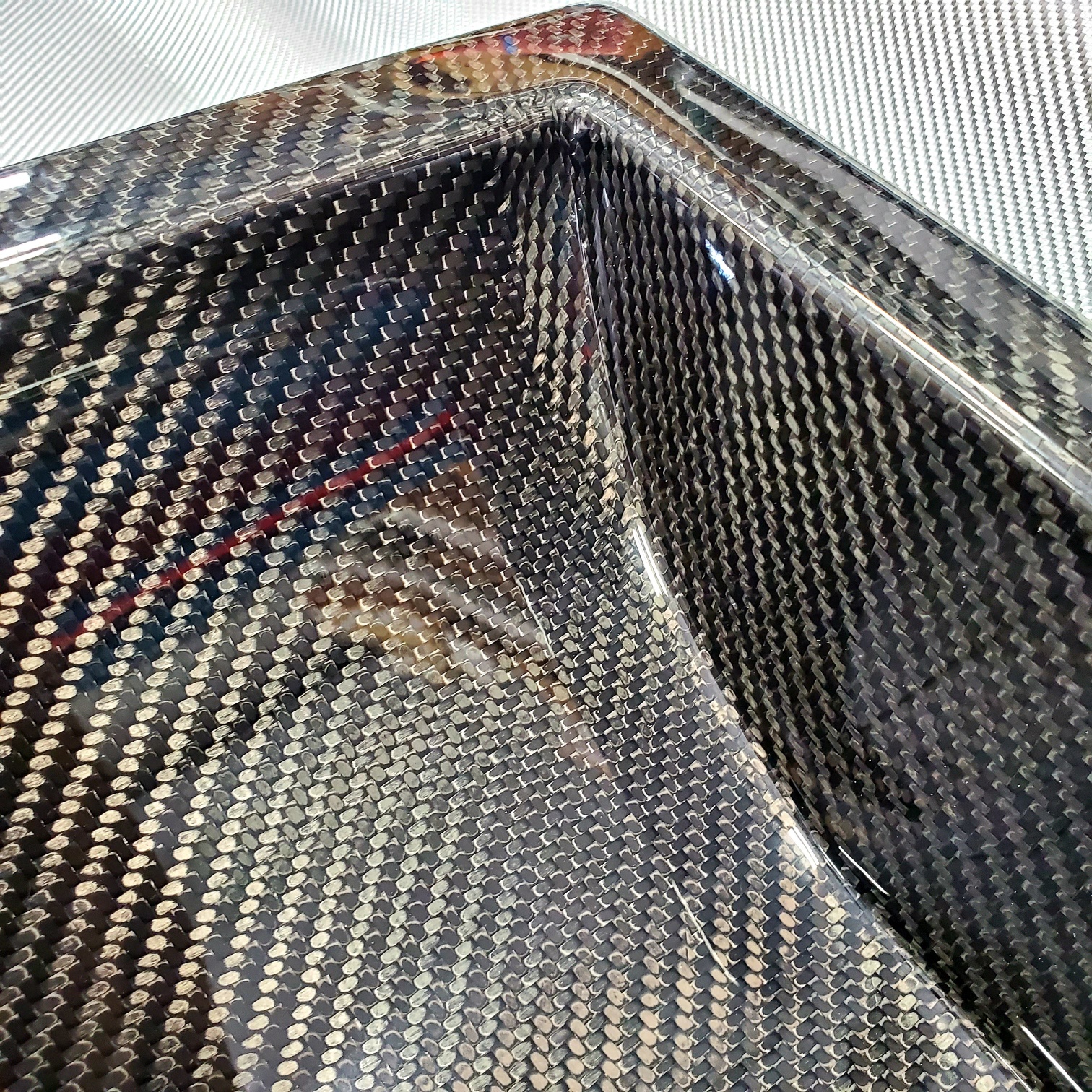

| Prepping Your Parts For Clear Coat | The clear coat application is what stands between a dull carbon finish and a shiny, … | Clear Coat, Composite Reinforcements, General Composite Knowledge, Tips & Tricks | 08/22/2022 |

| Humidity & Vacuum Film Tips | Ever take a sample of vacuum film straight off the roll and notice how unpliable … | Bagging Film, Composite Techniques, General Composite Knowledge | 08/22/2022 |

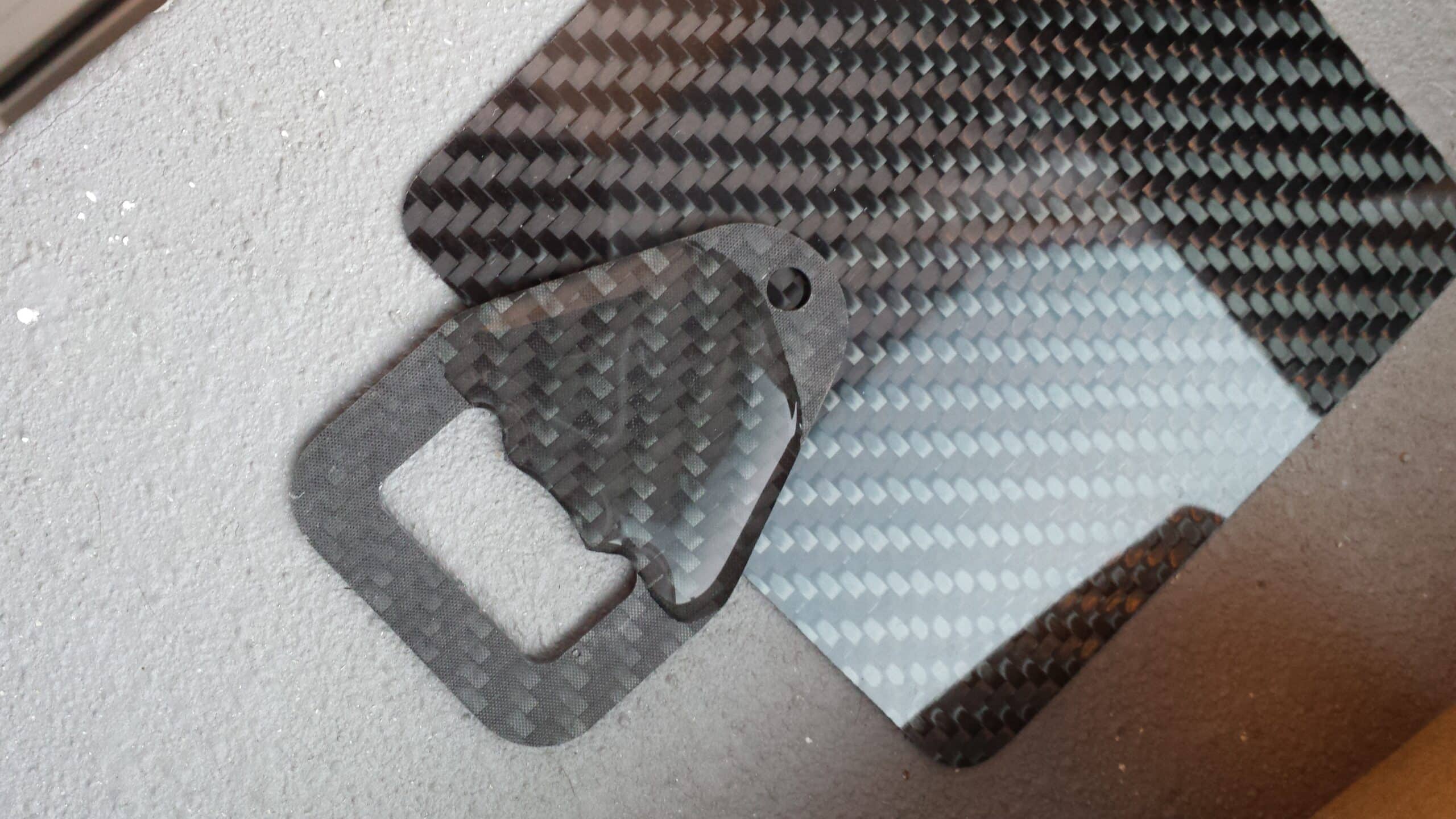

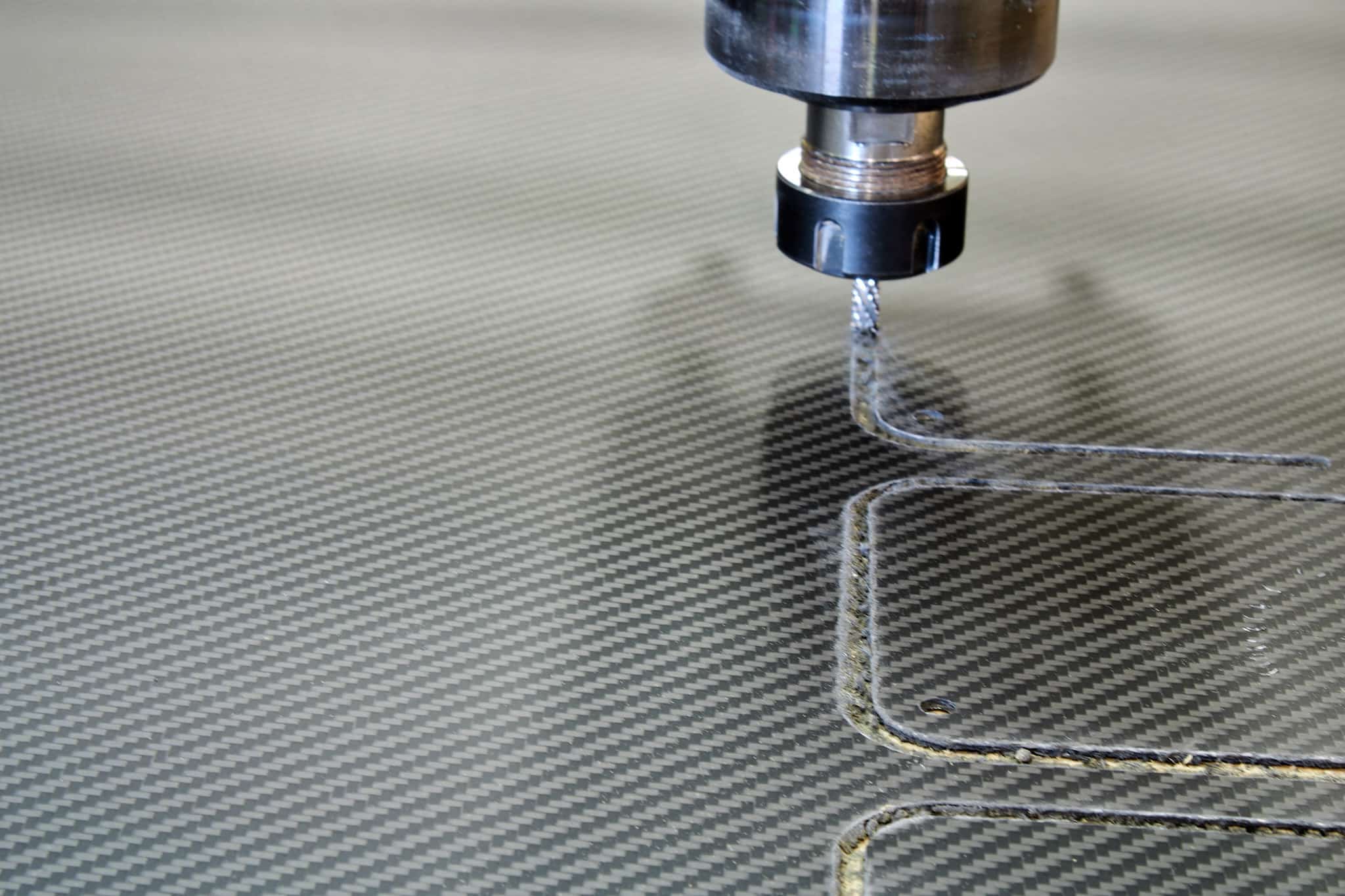

| Cut Quality From Various Tools | When trimming or cutting any cured reinforced fibers, all cutting edges of the tool are … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 08/22/2022 |

| Cracked Parts & How To Fix Them | Unfortunately, at some point you will run across an instance when your composite part cracks … | Composite Techniques, General Composite Knowledge, Tips & Tricks | 08/22/2022 |

| Composite Sleeving | Composite Sleeving is used worldwide to fabricate products ranging from aerospace grade rocket bodies to … | Aramid, Carbon Fiber, Composite Fabrics, Composite Reinforcements, Fiberglass, Kevlar | 08/22/2022 |

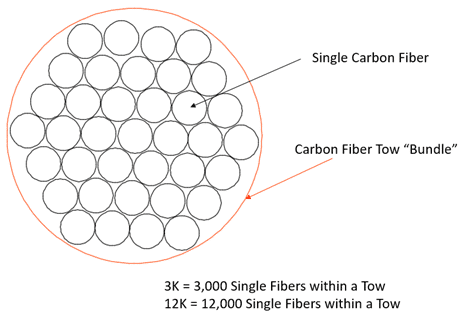

| What Is 1K, 3K, 6K, 12K, Denier & Dtex | Chemistry is a subject on the forefront of composite arts. Chemistry has everything to do … | Aramid, Carbon Fiber, Composite Fabrics, Composite Reinforcements, Fiberglass, Kevlar | 08/22/2022 |

| The Benefits Of Utilizing Prepreg In Your Layup | Murphy’s Law: a law of nature, anything that can go wrong will go wrong. This … | Composite Reinforcements, General Composite Knowledge, Prepreg | 08/19/2022 |

| The Many Ways To Layout Your Infusion Setup | There is an endless amount of ways one can feed resin into a given part … | Composite Techniques, General Composite Knowledge, Tips & Tricks, Vacuum Infusion | 08/19/2022 |

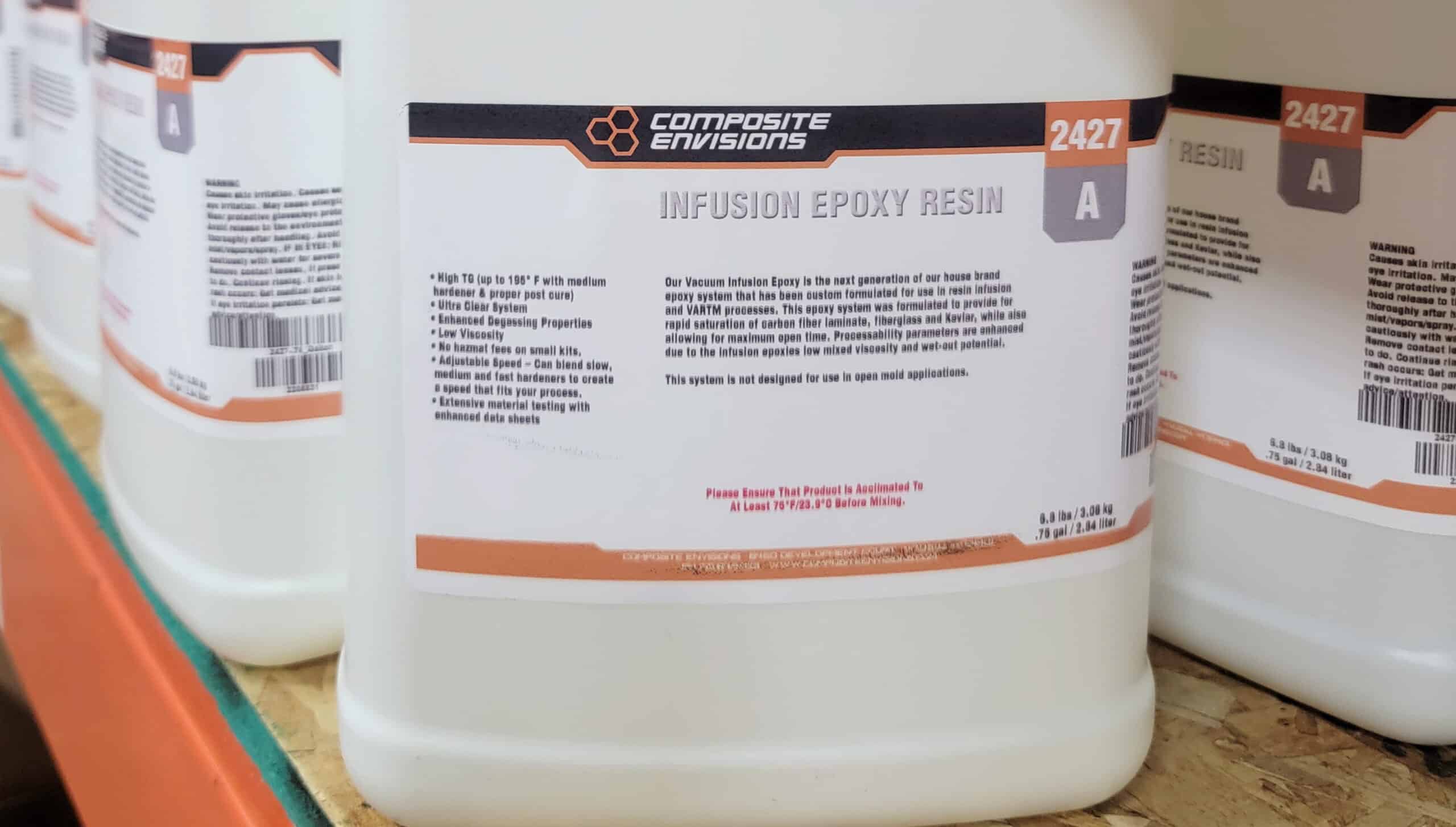

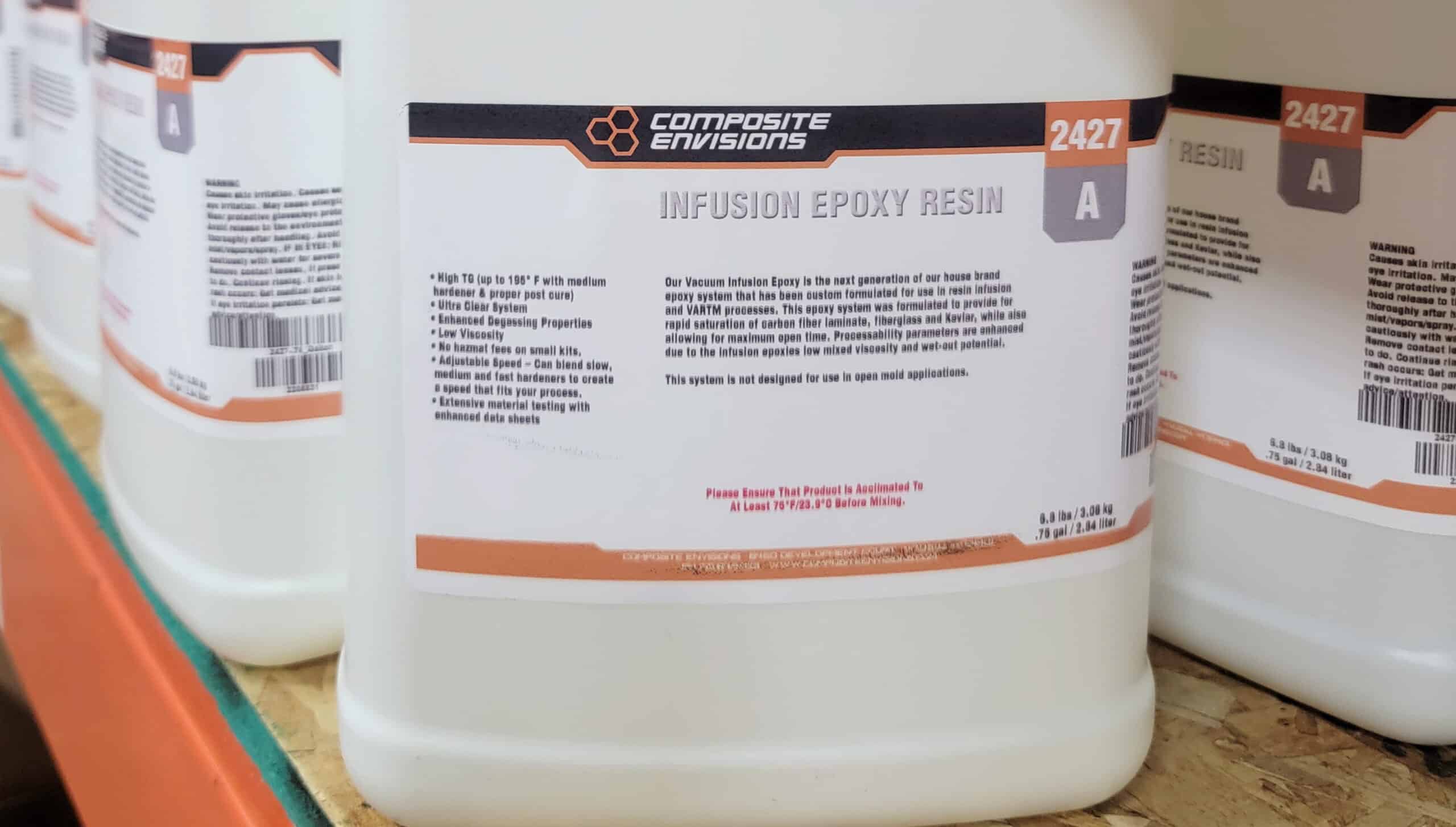

| Resin Selection | From the many choices of different resins, the main categories for high performance composites are … | Epoxy, General Composite Knowledge, Polyester, Resins, Vinylester | 08/19/2022 |

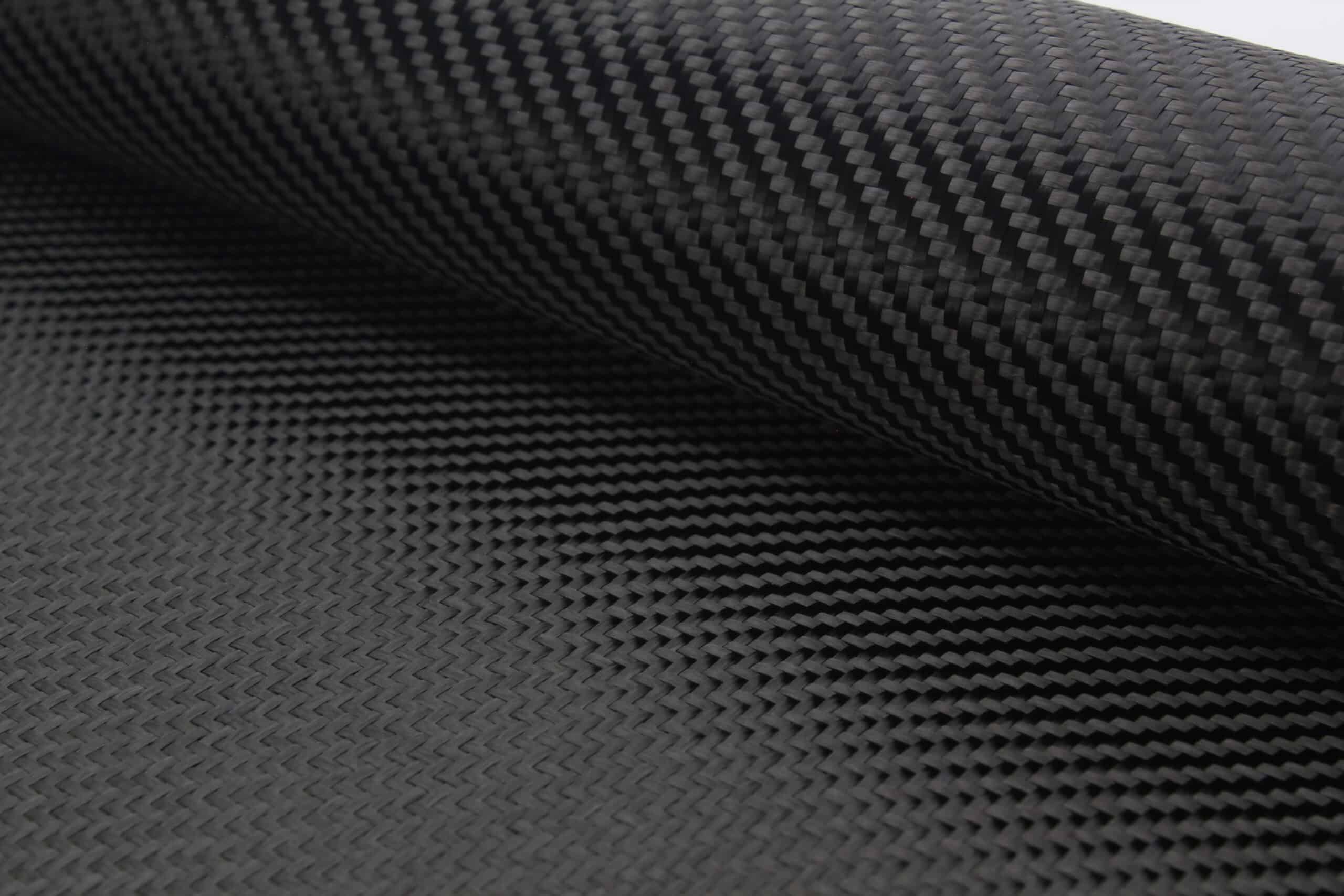

| Composite Reinforcements: Carbon Fiber, Fiberglass and Kevlar | There are three main types of reinforcements used in composites today: Carbon Fiber, Fiberglass, and … | Aramid, Carbon Fiber, Composite Fabrics, Composite Reinforcements, Fiberglass, Kevlar | 08/19/2022 |

| Core Materials | Core materials are added to composites for several reasons. One of the main reasons for … | Balsa, Carbon Fiber, Core Material, Mycell, Nomex | 08/18/2022 |

| Composite Fiber Characteristics | There are three main types of fibers used in composites today; Carbon Fibers, Fiberglass, and … | Aramid, Carbon Fiber, Composite Fabrics, Composite Reinforcements, Fiberglass, Kevlar | 08/18/2022 |

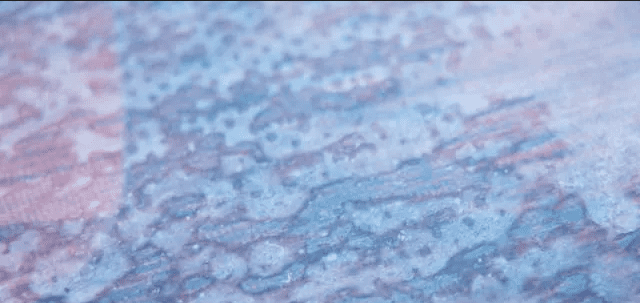

| Preventing & Resolving Epoxy Resin Crystallization | Crystallization of epoxy resin formulations is not uncommon and in some cases is a reflection … | Epoxy, General Composite Knowledge, Resins, Tips & Tricks | 09/8/2021 |

| How to Fix Snags | To fix a snag like the ones above, pull from location 1 & 2 at … | Composite Fabrics, General Composite Knowledge, Tips & Tricks | 03/16/2021 |

| Removing Bubbles in Resin | Why Remove Bubbles From Your Resin? Removing bubbles ensures optimal adhesive performance by providing a … | Composite Techniques, Epoxy, General Composite Knowledge, Resins, Tips & Tricks | 03/16/2021 |

| Amine Blush | What is amine blush? Amine blush is a waxy bi-product that appears as epoxy cures. … | Epoxy, General Composite Knowledge, Resins | 03/16/2021 |

| Composite Terminology | Aramid – The term aramid denotes a class of aromatic polyamide fibers and includes Kevlar® … | General Composite Knowledge | 03/16/2021 |

| Best Practices For Mixing Epoxy Resins and Hardeners | Before You Start Mixing Working with epoxy can be highlyrewarding, as well as safe. Serious … | Epoxy, General Composite Knowledge, Resins, Tips & Tricks | 03/16/2021 |

| Composite Fabric Weave Styles | Most weave styles consist of strands of material running the length of the fabric, known … | Aramid, Carbon Fiber, Composite Fabrics, Composite Reinforcements, Fiberglass, General Composite Knowledge, Kevlar | 03/16/2021 |

| Woven Fabric Guide | Types of Fiber The three commonly used fibers in a woven fabric are Fiberglass, Carbon, … | Composite Fabrics, Composite Reinforcements, General Composite Knowledge | 03/16/2021 |