Vacuum bags are one of the most versatile tools used in the composite industry. For fabrication of complex shapes and thicker laminates, vacuum bags offer many advantages in composite processing. When an airtight seal is placed on parts using a vacuum pump or venturi system, pressure added to the plys by the vacuum bagging film creates an evenand consistent consolidating pressure over the entire part. This pressure is proven to drive laminate quality to its highest marks.

Vacuum bagging films come in an array of sizes, shapes, colors, materials, and thicknesses. There are many variations of bagging materials one can select from for a given process in composites and often more than one film will get the job done. However, proper selection of a vacuum bagging film will produce the most efficient and effective processes for any composite fabrication and ensure the highest part quality. Attention to detail is of utmost importance with bagging, it is as much an artform as the layup process in fabrication of the composite laminates.

Most often the following criteria are used for selecting the proper bagging film for a process. The following (2) criteria should be followed before all else.

Temperature Capability: The bagging film must be able to withstand the temperatures used in each composite’s cure cycle. This will ensure stability throughout the cure process. Chemical Compatibility: The bagging film type must be compatible with the resin type(s) used. Bagging Films made from Nylon are widely used throughout the composite industry due to the versatility in providing variations of temperature resistance, flexibility, puncture resistance, and price in composite processing. With the exclusion of phenolic resins, nylon bagging films are compatible with nearly all fabrication methods. Differing chemical types of material are used for bagging films, including silicone, polyamides, and other thermoplastic elastomers. These different bagging films are formulated to provide additional stretch, a certain chemical resistance, breathability, or temperature capability. It is important to review each technical data sheet before making a final decision on the specific bagging film used in fabrication.

Once the bagging films have been narrowed by chemical & temperature compatibility, the options are levied by preference of the fabricator based on the needs of the part being built. With the above criteria covered, a high performance, quality laminate can be made. Although the below criteria are preferences, each characteristic carries high importance with consolidation, ease of process, and even the final quality of the part.

Elongation, also referred to as flexibility, elongation at break and tear strength are characteristics of a bagging film that allow the bagging film to conform to tight radii and changing contours in a part’s surface. Bagging films that are more flexible are less likely to bridge a part. Elongation properties are added to certain bagging films to make processes more efficient and to mitigate issues that come with complicated bagging schemes. In short, bagging films with higher elongations may offer a higher degree of forgiveness vs standard films. Especially when considering the high number of pleats a bag may need for a large complicated part. For someone just getting into composite bagging processes, a bag with higher elongation properties will aid in overall part quality. In corners or female radii along the tool, it takes only a small bridge in a vacuum bag to result in the part being resin rich, having issues with porosity within the parts radii areas, or worse, blowing a bag during cure which could result in a scrap part.

When performing work with prepregs, resin infusion, or traditional style layups, the thickness of the bagging film plays a role in bagging processibility and the part’s cure. Thicker bagging films usually offer an “easier” degree for workability than that of thinner bags in that they do not fold over or crease as easily as thinner selections. Although most bagging materials carry a standard 2 mil thickness, Prepregs and traditional layup’s using vacuum will benefit most by using thick, soft, and flexible bagging for most complicated layups and bagging schemes. However, when performing resin infusion processes, using thinner or stretchy bagging films may slow the rate of resin flow vs a standard film. This is also relative to sizing of bags and projects that may be applied to.

A bagging film’s width should always be taken in consideration for economical purposes. For instance, if a project is a small part with a tool width of ~12”, the need for using a bagging film with the width of 120” would not be economical. On the other hand, for a boat hull or fuselage of an airplane, wider bagging material widths are integral for processing effectively and choosing the correct bagging material is of utmost importance. It is always better to have a bagging width that is too much than not enough. Generally, choosing a film with a width that is 30-40% greater than that of the tooling surface should provide an adequate amount of material for pleating around the edge of the tool. For more complex contours of the part, the bag should widen considerably as more pleats should be added around the edge of the part. The exact figure of bagging widths is not usually done in one part. Repeating processes usually gives better and more efficient numbers.

Vacuum bagging film can also be affected by the humidity conditions present in the area it is stored and exposed to. In areas on low relative humidity some bagging films will become more harder to work with and may feel as if they are brittle. When exposed to areas of higher humidity, these films usually become softer and easier to work with. Some bagging films, such as Airtech’s Stretchlon series films will keep the same properties in lower humidity conditions and provide consistency throughout the bagging process.

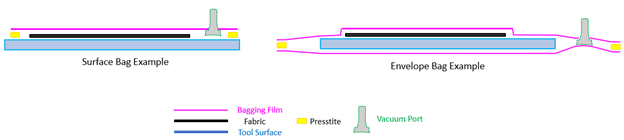

Vacuum Bagging Film selection is also dependent on the application of method onto the tooling surface. The two main application methods are surface bagging and envelope bagging. Though there are additional ways to back a part, these two methods cover 99% of general bagging arrangements. Usually the tool configuration will be the best guide in deciding the technique to use.

Surface bagging is the most used type of bagging application in the composite industry. The bagging film is placed and sealed on top of the mold surface. Usually the layup tools are designed around the process of surface bagging part as flanges are made past the part’s layup lines on the tool to offer areas for “presstite” to stick to the bagging surface and tool. Any of the bagging films may work for this application based on the criteria of the part needs.

Bag & Breather 2 For 1

Certain bagging films are also designed to act as a complete system rather than just a film. Airtech’s Airdraw 2 removes the need for a breather material between the layup and the bagging film. This embossed film will cut costs in using breather and simplify composite processing all while providing air passageways for producing full vacuum pressures faster.

Aerovac Vacuum films offer a wide range of innovative high-performance bagging films. Their product lines serve industries worldwide including aerospace, wind energy, marine, and motorsport applications.

VACFILM 800G bagging film offers a high range of versatility in selection of widths and high temperature capability. This nylon vacuum film offers the same elongation of Airtech’s Stretchlon line, proving conformity to even the most complex parts. If that is not enough to give this material a shot, its unmatched bagging strength makes it ideal for aerospace bagging and manufacturing processes. This budget friendly film will provide the pressure to suit nearly any composite bagging application. The bagging film is compatible with Epoxy & some BMI resins up to 400°F

Airtech is the world’s leading supplier of composites bagging material and has the widest selection of bagging types for composite application. Though they have a huge selection in terms of bagging films, Airtech provides a category in which it was designed.

Securlon bagging films are made for commercial grade parts for utmost quality purposes when used in high temperature cures where high elongation and strength are of the highest concern. These films are multi layered in composition and provide the safest option in bagging films.

Stretchlon bagging films are nearly self-described in the name of stretching. Some Stretchlon films will elongate to 500%! The Stretchlon line offers this high stretch for differing temperature applications, resin types, and budgets. Stretchlon will aid in bridging the gap of inexperience and producing high-quality laminates in almost any layup scenario. Wrightlon films are Airtech’s original nylon film. It has been used and tested more than any other bagging film type to date. It is a proven product line that is still used to this day. Ipplon bagging films are an extension of the Wrightlon bagging films, adding versatility in strength and softness for a higher degree of workability for elevated and pressurized cure cycles.

Econoline bagging films offer a secure nylon film for room temperature cures and are often used for debulking within a part’s layup scheme. The Econoline is Airtech’s budget minded line that will produce high quality laminates the same as any other line available. Ultra-High Temperature Films are specialty films designed to produce parts in cure cycles up to 750 F while keeping decent elongation figures.

Many composite parts are made from the bagging selection above. However, there is no restriction in using other types of materials that can be used for bagging processes. There are many options in silicone type bagging films that offer unique advantages over conventional bagging films. These types of bags have an array of applications and are often reusable in composite bagging schemes. These advancements in bagging films have been described as game changing to the composite industry.

These bagging films can be used with resin infusion and traditional layup methods and autoclave cures dependent of the service temp of the materials used for the bagging film. These is most chemically compatible with Polyester, Vinylester and Epoxy layups. Phenolic resins may pose a challenge; however, Teflon release or barrier films may be used to mitigate issues related to phenolic resin’s corrosive nature.

Silicone Background

Silicone is one of the most widely used rubber like substances on earth. When Silicone is used as a bagging film, it’s versatility, flexibility, strength, and durability characteristics provide for a high-quality reusable bagging film in the even the most high-performance composite application. The main advantage of silicone bags lies in manufacturing parts with little degrees of variation in the bagging process. Ending with a high degree of repeatability throughout the cure process.

Advantages

Silicone bagging may sound like more than it’s worth for one off parts or tools that may not see more than 5-10 cycles, but as for repeatability, Silicone bags are revolutionizing composite manufacturing. In addition, this process provides reduced production costs over time as fewer “expendable” materials are being used and/or wasted. The ease of bagging reduces labor in time of bag application as it simply goes over the uncured part with relative ease.

Disadvantages / Limitations

Some silicone bags can be complicated, some even more complicated than the layup itself. The cost of the material is generally much higher than that of a single use bag. Experience plays a key role with getting a custom fit bag for reusable bagging films. The learning curves that go along with formation of these bagging types are comparable to composite parts themselves. One key factor in mitigating these growing pains are using a real, acceptable part or plug for fabrication of the bags.

Types

Silicone bags may be made from many different fabrication methods and the design process of some bagging types can be just as complicated. The time spent exploring the options for design in silicone bagging processes could eliminate many problems that arise from using conventional bagging films when industrializing processes for manufacture. There is not always a right or wrong answer when selecting and designing for specific fabrication processes. Below is an overview of some silicone bagging types and fabrication methods. While all the fabrication steps are not listed, the following will give an overview for selection of the possible type of silicone bags that could be used or designed for a given project.

Spray-On Silicone Bag Applications

“Spray-On” Silicone bagging films are made by dispensing silicone material through a nozzle using a spray gun and applying it to a tool with a plug or cured part usually already on the tool surface. Because silicone doesn’t usually stick to anything other than itself, it can be applied to a clean mold / part surface. One of the most important pieces of the spray on process is proper mixing of the silicone during the application. Basically, one would start spraying onto the surface with multiple layers until the desired thickness is reached for the parts, usually being thicker for larger parts but using (~1/4”-1/2”) as a baseline thickness. Vacuum port inserts, reinforcement fabric, and breathable airways may be added as part of the fabrication process.

The advantage of the spray application lies in its ability to conform to an already cured part and mold surface. What one sprays onto the surface will be consistent and intimate to with the tool / part used. Consolidation of plys through the layup procedures are then standardized by the bag through the cure process. This eventually leads to higher control of final part thicknesses and eliminates variation in bagging processes.

Disadvantages & Limitations

The main disadvantages to the spray on type of bag are the variables that go into fabricating the bag. On one hand, once a good silicone bag is achieved, part consistency and quality are higher. On the other, getting a good bag from the spray method can be messy and great care must be taken through the process. Cleanliness is key and ensuring correct setup is a must for success. Tools and spraying mechanisms must be cleaned and inspected before each use. It is common practice to test the process successfully a few times before actually making a vacuum bag. Once experience is gained in proper mixing and cure, this process can be just as easy as making a single bag in a conventional method.

Initial startup costs of some systems within sprayable bagging can be as much as $10k for a industrial setup, which may seem astronomical to some applications. Other limitations to this method are brought upon spraying onto vertical / transitional surfaces on larger tools. Often it can be very tough to apply the sprayed liquid silicone evenly and adequately over complicated surfaces along the tool or part. While it is not impossible to apply this method to vertical surfaces, experience with a given system are needed and additional processing may be required dependent of the types used.

Silicone Rubber sheets may also be used for providing a vacuum bagging film surface. Variations of widths and thicknesses and fabrication methods are available for almost any application need. Multiple layers are placed upon the tool and mold surface (as the spray method) It can be applied surfaces on its own to provide a reusable film for vacuum pressure.

Silicone bagging options include the ability to form to custom shapes and sizes. The options for this bagging type are nearly endless. When parts have multiple contour changes and vertical bagging surfaces, parts may be bagged quicker and easier by using this method over all others. Preform sheets may be used that are purchased as uncured. Coming off a roll, these soft and workable rubberlike sheets are laid up onto a cured part to a desired thickness and are cured by vulcanization (heat) to form an elastic and reusable bagging surface. These bags may be designed thicker in high stress areas and may be fabric reinforced (usually by twill or woven fiberglass). Formable silicone bags have proven to provide ease in bagging & demold processes in comparison to conventional bagging methods. These methods eliminate the messy nature of sprayable bagging and mitigate variation during the bag fabrication process. The only main disadvantage to using this type of bagging process is the need for a high heat cure and post cure. Temperatures needed for cure usually consist of 300 to 400 ºF.

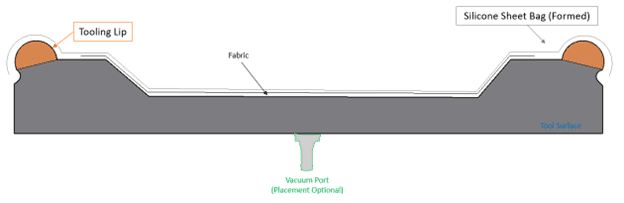

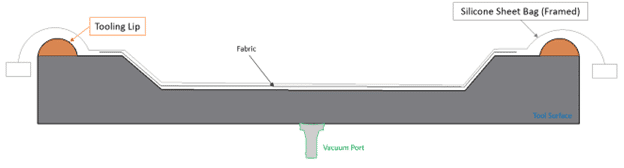

As an option, sheets cured of silicone may be used with tools that have vacuum application applied inside of the tool and draw vacuum down differently than conventional methods of vacuum port placement. In the case illustrated below, instead of a vacuum port being on the bagging film surface, it is integrated into the tool. A lip is added onto the layup tool surface for initial pressure buildup for the silicone sheet (bagging film) to be sucked down to the part and underlying tool surface. These types of bags hold higher standards than even Airtech’s Stretchlon line in terms of flexibility and elongation and come in differing thicknesses and temperature selections based upon application need. Heated cures are not needed when using the precured sheet method.

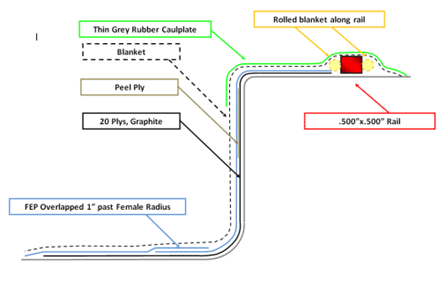

These types of sheets are also made to be used as intensifiers or caulplates under conventional bagging films as part of some overall bagging schemes. Though it may look complicated, in application these sheets have been proven to provide higher laminate quality in male and female radii and along laminates that are prone to wrinkling. (As shown below)