Description

CB1100 is fully compatible epoxy and HTM Bismaleimide (BMI) prepregs and can produce thermally stable composite tooling capable of withstanding the high pressures and elevated temperatures associated with autoclave cure cycles.

The CB1100 ceramic tooling block can be used as a high temperature capable master model. Machining times are short and, because of its very low thermal expansion, CB1100 is also particularly suited to the production of high accuracy, short run and prototype tooling, where it can save time and money.

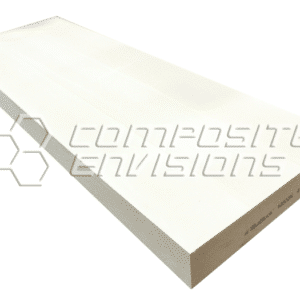

Size of blocks are 19.75″ x 19.75″ and available in 2″ and 2.75″ thicknesses.

BMI tooling produced with a CB1100 core can be produced direct from the block without the need for a high temperature capable intermediate. CB1100 blocks can be fabricated and machined to form a tool core, totally eliminating the need for a master model.

By applying a composite tool skin, laminated directly to the core you are able to produce a very accurate tool. The carbon tool skin is fully supported by the ceramic core so there is no need for a backing structure. The tool face is CNC-machined to create the final surface profile, thus overcoming accuracy issues created by intrinsic laminate shrinkage, resulting in an exceptionally accurate and stable tool.

CB1100 does not absorb water so it does not require drying or subsequent venting of the tool, and it is incombustible.

Reviews

There are no reviews yet.