Core materials are added to composites for several reasons. One of the main reasons for core material is to increase the thickness of the part. Composite cores can effectively thicken parts as much as the core is designed for as it comes in an array of thicknesses and application methods. Usually core material is low density and will drastically increase the stiffness of parts while only adding a minimal amount of weight to the composite. When core is added to the design process, it is often called a sandwich structure because the core material is sandwiched by the fabric and resin matrix, the end result is the core material acting as it were effectively an I-beam in construction.

One of the biggest questions surrounding cores is the selection for a given project. There are plenty to choose from including balsa wood, honeycombs, open and closed cell PVC & Urethane foams, pourable foams, and shredded materials that are designed to get the highest performance from a given composite structure or fabrication process. As cores come in differing thickness needs per application, core materials are ultimately designed around their shear strength and stiffness ability. Each core material will add rigidity to a composite, some core material types more than others. However, core material has its own process parameters that also determine how well or how easy it may be applied to a structure. Some cores have differing chemical, thermal and water resistances, conductivity properties, and crush strengths. Some are easier to machine than others while some do not require additional processing. Below will provide detail on which direction a project should go based on each layup process and resin type.

Most composite layups are processed by infusion, wet layup, or prepreg application. Some types of core materials simply are not designed for certain types of layups and / or cure parameters. Some core materials are specifically designed around prepregs or traditional layups while others are used specifically for infusion. If a workable process is established for fabricating parts already, these types of core should be used.

| Core | Infusion | Traditional (Wet-Layup) | Prepreg |

| Soric Infusible Core Materials | Yes (1) | No | Yes |

| Coremat | No | Yes | No |

| Nomex Honeycomb | No | Yes | Yes |

| Balkore (Balsa Wood) | Yes | Yes | Yes |

| Mycell (PVC Closed Cell Foam) | Yes (2) | Yes | Yes |

Advantages: For the Lightest, Most Rigid Components providing proven high performance

Disadvantages: Cost, Experience needed for processing & machining in complex structures Honeycomb cores offer the highest performance in core selection today. The hexagonal core shapes (honeycomb) and the Aramid fiber / Phenolic resin makeup give the core structure its strength. From commercial and military aircraft, auto racing, transportation, and construction industry; this core material is the top of the line.

Simple Panels

For flat panels and simple contours on a core exposed sandwich panel, Nomex honeycomb cores are very easy to work with. A razor knife will cut through the material with relative ease if a sharp blade is used.

Note: Nomex Honeycomb cores are only waterproof if encased within a composite matrix. Otherwise, the core will be subject to water intrusion.

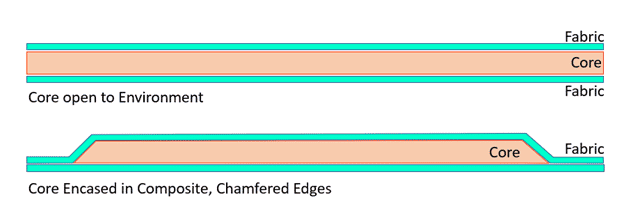

may need to be chamfered to successfully encase & co-cure in a laminate. Traditional layup methods are generally used when secondarily bonding the cores between 2 cured compositeskins. Both applications have advantages depending on the processability and end use needs.

See above for an example of a chamfered edge vs a straight edge that yields a simple sandwich panel. A chamfered edge provides a means in which the plys will not need to go straight down, causing wrinkles, porosity, and other quality issues. A chamfer will provide optimum laminate composite quality in a co-cured sandwich laminate.

Cutting Nomex core can be a delicate process that requires patience and experience to perfect. Especially if there is not a 5-axis CNC machine just lying around. As option, use a small amount of honeycomb material to experiment, learn how it reacts to certain cutting tools, applications, and even the orientation of the core while it is cut. If one does enough research, there are many ways Nomex cores can be cut, though some of them are easier than others.

The first step in cutting Nomex Honeycomb core is to somehow stabilize the structure along

the areas in which will be cut.

If cutting straight thru the core a sharp OLFA type razor blade will suffice. Some engineering / workability will need to be setup to achieve a chamfer. A simple workstation such as a Dremel 220 can be applied to a rotary tool with a cut off wheel to achieve the cut at the angles needed. Usually 45º is a good starting point for a chamfered edge but there is nothing to say the core cannot be cut a steeper or shallower angle. It is advised to use the maximum number of RPMs that a given rotary tool can provide and to cut the core slowly.

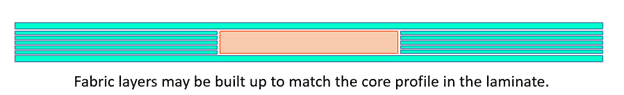

Lantor Soric line of polyester non-woven core material that geared toward Infusion processes. Each line exhibits a hexagonal structure for added compression resistance and rigidity over that of Coremat. Soric cores also double as a flow media in resin infusion and may eliminate the need for additional flow media or peel ply. Although there are PVC and other foam types of core that may yield lighter weight composites, none of them are easier to use in infusion layups that the Soric line of infusible core. It is soft and easily formable, flexes over contoured surfaces, and is easy to cut. Soric has a few lines of core material that are all similar but are geared toward obtaining the best characteristics in terms of thin or thick laminates, density, flow rates, and aspects of high-quality surface finishes. Unlike Honeycomb cores, Soric does not need to be chamfered to encase in a laminate structure. (though it can be chamfered). It may be much easier to simply match the reinforcement thickness around where the core material is laid up as shown below.

Lantor Soric XF line is very comparable to that of the SF line with the main difference being the application method and the flow rate of resin. The channel sizing of the XF line is larger, allowing higher flow rates of resin; being available in thicker sizes thus allowing for thicker laminates.

Lantor Soric TF line promotes the best surface finishes. It does not have the flow channels, so the rate of resin flow may not be as fast, but the print blocking is maximized. It is slightly heavier when impregnated than the above choices. Soric TF is also offered in a Dark Grey color to achieve a black carbon fiber look in laminates.

Lantor Coremat (Budget Minded Choice) is used for adding bulk to traditional layup methods for all conventional resin type needs. Simple in its design of shredded polyester material, it adds rigidity and thickness to parts, and is a great time / cost-effective solution for core needs of traditional layups. This core material will also control print through. Coremat is easy to trim, being cut by hand and

even easier to apply in layup processes.

Foam cores share a wide range of applications and uses in addition to being applicable with polyester, Vinylester, and epoxy resins. Foam offers one of the most light-weight solutions in core materials. One of the biggest factors in selecting a foam core is the open vs closed cell structure within the foam. For sandwich composite structures, a closed cell foam should be used to so that the core does not absorb resin during cure under vacuum. A resin filled foam core is neither light nor strong. Closed cell foams take in virtually zero resin in the cure process.

Foam cores, such as PVC foams offer a much lower density solution than the Soric or Coremat lines. However, they lack in terms of strength. Foam cores will still add good compressive strength within a structure but not as high as other options.

All foam cores can easily be cut with hand tools such as a razor blade and formed with a block sander to create the desired chamfer angle in the core material as needed. For thinner laminates, the fabric layers may be matched to the foam core’s thickness to mitigate any possible bagging issues.

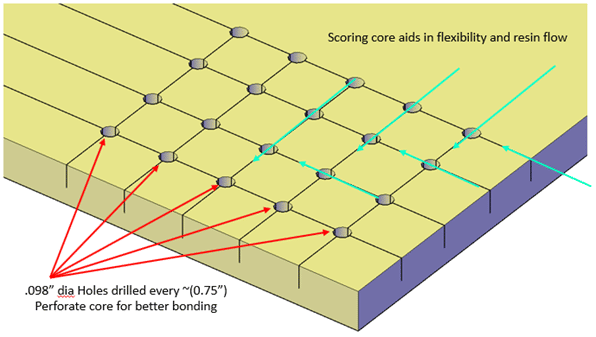

As easy as closed cell foams are to machine or cut in placement in a part, there are challenges around pin holes, dry patches, bridging, and voids within a co-infused laminate using foam cores. Epoxy resins will stick to cores with less of an issue. However, relying only on the vacuum pressure to pull Polyester or Vinylester resins across the foam core can lead to such issues as the closed cell foam does not take resin well. To solve issues such as pin holes, dry areas, and other quality issues, the foam core will need to be perforated, having holes drilled into it for the resin to fill adequately. To perforate core, drill holes in the foam core with a ~.098” drill bit for every 3/4” of foam and score foam between the holes as illustrated below.

Foam core may also be secondarily bonded to 2 cured laminate skins using an adhesive layer between the skins and the foam core. This would make a lot of sense in doing if fabricating simple or flat parts but is not limited to that.

When processing or working with foam core before cure, be mindful that it may crush easily. Be sure to never place too much pressure on the foam’s surface or it will likely scrap the core piece. Do not place foam cores in areas that will be commonly walked over or common to bumping into. These issues can be mitigated by transporting and storing (ALL) core materials between cardboard sheets, protecting the foam or other core material inside. If foam core machining or if complicated shapes are in issues with utilizing core materials, one option is pourable expanding foam cores. When poured into a given mold or shape, the foam cores expand and fill to give a desired shape to lay up over. Expandable foam cores come in an array of densities and resin type applications from polyurethanes to epoxies.

These cores exhibit the same mechanical properties as comparable sheets but cut costs and time behind working or machining core pieces.

Balsa wood core material utilizes the same hexagonal shape in it as honeycomb cores. However, it usually is not seen by the naked eye. Balsa wood’s honeycomb configuration comes from its molecular structure. This molecular structure compliments its high strength to weight ratio as a great choice in a sandwich structure. Balsa cores are processed much like that of foam cores, though offered in thicker options. They may be co-bonded / infused into the part or secondarily bonded. The same principles with scoring to conform to complex shapes are an option when utilizing this core material.

Balkore also offers the Balsa core grid scored for conforming to complicated surfaces and “scrimmed”. The scrim aids in its bonding capability while allowing for additional flexibility on the opposite side. Balsa wood may be cut or machined with chamfered edges just as foam, honeycomb may be. Balsa is not as easily chamfered or cut as foam but still much easier than Nomex honeycomb. Balsa is a great choice for any layup technique and is compatible with all conventional resin types.