Description

This fabric has a width of 50″, tow size of 12k, and is woven in a 2×2 Twill. Thickness .008″. Made with Toray T-700 Fiber.

Hexcel part number 48194.

PrimeTex®

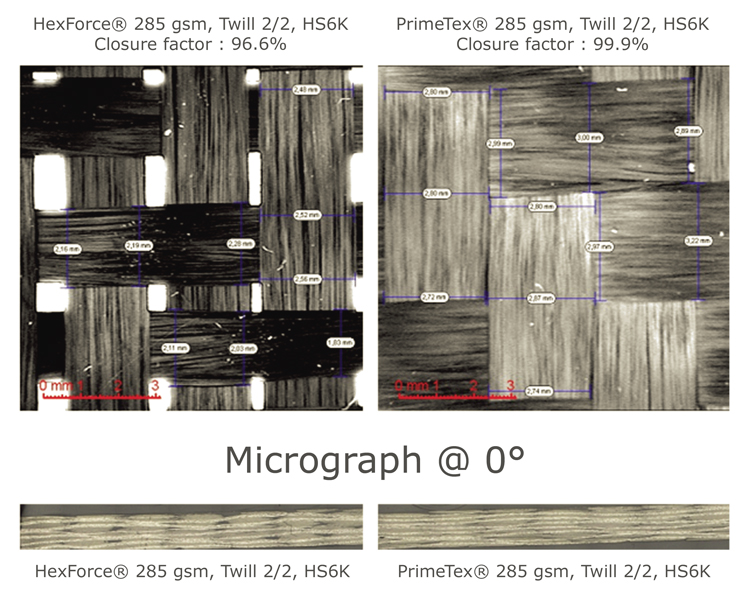

PrimeTex® is a range of carbon fabrics that have been processed for a smooth, closed weave and uniform cosmetic appearance. The fiber tows are spread in both the warp and weft direction for unique aesthetic appeal. PrimeTex® fabrics are more uniform as the filaments in each tow are spread out, creating a thinner and more closely woven fabric that provides better mechanicals and less porosity in a composite. It can also be used to lower the mass in a composite where lighter weight is the key characteristic.

- Patented technology with fibers spread in both the warp and weft direction

- PrimeTex® spreading process improves closure factor compared to conventional weaving process (depending on carbon tow and Fabric Areal Weight)

- Use of higher K tow for a given Fabric Areal Weight (FAW)

- Weight saving: Up to 20% at an affordable cost when replacing HS3K by IM12K

- Uniform weave and gap-free structure: porosity reduced / less labor for part finishing

- Excellent water tightness when used in honeycomb sandwich structures

- Laminate mechanical properties maintained after spreading process with reduced variability thanks to homogenous resin/fiber distribution

Typical Applications:

- Aircraft and helicopter sandwich structures and thin monolithic parts

- UAV/Light Aircraft market targeted by cost to weight

- Automotive structures (e.g., BMW roof)

- Sports equipment (e.g., skis)

To harden the raw fabric into a usable form, you will need the appropriate resin or epoxy for your project.

First Quality Remnants:

First Quality Fabric Remnant Rolls are short rolls of fabric, which have no defects in them. These remnant rolls are either leftover fabric from the end of a roll or sections of fabric cut at the wrong length for a specific order. So instead of discarding the short roll, we package it up and sell it as a First Quality Remnant Roll. These First Quality Remnant Rolls are sold at 20% off of the retail price of that fabric.

Second Quality Remnants:

Second Quality Fabric Remnant Rolls are short rolls of fabric, which have a defect in the woven fabric in them. These remnant rolls are cut out of the standard fabrics we sell but from sections of the rolls that may have some defects in them. These defects make them not good to use if you want to make cosmetic parts, which have a perfect woven fabric in them but can be used as the inner layers of your parts, or if you are making small parts and can cut around the defects. These Second Quality Remnant Rolls are sold at 25% off of the retail price of that fabric.

All remnant rolls are rounded DOWN to the nearest ½ yard. So a remnant listed as 0.5 yards may actually be between 18” and 35” in length, and a remnant listed as 2.0 yards may actually be between 72” and 89” in length.

Reviews

There are no reviews yet.